Time: 2025-04-15 12:35:38 Source: Henan Province Jianyun Cable Co., Ltd.

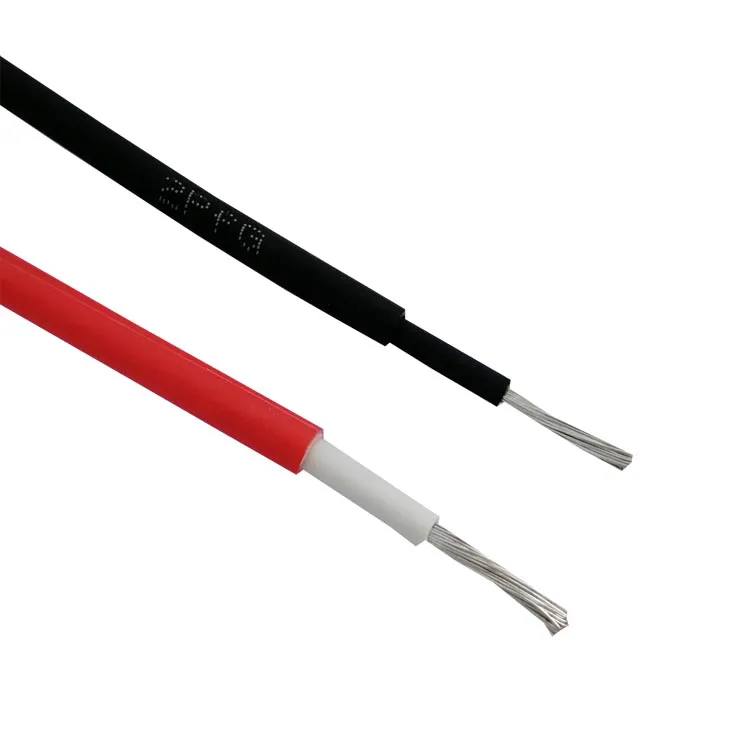

Solar cables, also known as photovoltaic (PV) cables, are specialized electrical cables designed for use in solar power systems. Unlike standard electrical cables, solar cables are engineered to handle the unique demands of PV systems, such as prolonged exposure to sunlight, temperature extremes, moisture, and UV radiation. They typically consist of a conductor (usually copper or aluminum), insulation (often cross-linked polyethylene, XLPE), and an outer jacket (e.g., PVC or halogen-free materials) to protect against environmental factors.

The primary role of solar cables is to transmit electricity generated by solar panels to other components like inverters, charge controllers, and batteries, ensuring minimal energy loss and maximum safety. For example, in a solar power plant, solar cables carry direct current (DC) from panels to an inverter, which converts it to alternating current (AC) for grid use. Their importance lies in their durability and reliability—poor-quality cables can lead to energy losses, overheating, or even fires, jeopardizing the entire system. Think of solar cables as the arteries of a PV system, delivering lifeblood (electricity) to keep the system alive and thriving.

Solar cables are classified based on their design, conductor material, and application within a PV system. Understanding these classifications helps in selecting the right cable for specific needs.

For instance, PV Wire is often used in ungrounded PV arrays due to its thicker insulation and better resistance to sunlight and temperature extremes compared to USE-2. Classifying solar cables is like sorting tools in a toolbox—each type has a specific purpose, ensuring the right fit for the job.

Solar cables must meet stringent standards to ensure safety, performance, and environmental compliance. These standards classify cables based on their ability to withstand electrical, mechanical, and environmental stresses.

These standards ensure solar cables can endure the harsh conditions of solar installations, much like a ship’s hull must be built to withstand stormy seas—without the right specifications, the system risks failure.

In residential solar installations, solar cables connect rooftop panels to inverters and batteries, enabling homeowners to harness solar energy for household use. DC solar cables, often pre-built into panels, link individual panels in a string, while main DC cables connect the string to the inverter. AC cables then deliver the converted electricity to the home’s electrical panel.

For example, a typical rooftop system might use 4 mm² DC cables (e.g., PV Wire with copper conductors) to handle the current from panels, rated at 600V to 1500V DC. These cables must be UV-resistant and weatherproof, as they’re exposed to sunlight and rain. Ground cables are also used to ensure safety by providing an electrical ground. In a residential setting, solar cables help reduce electricity bills and reliance on the grid, acting like a bridge that brings the sun’s energy directly into your home.

In commercial and industrial settings, solar cables support larger-scale PV systems, powering offices, factories, and warehouses. These installations require robust cables to handle higher currents and voltages. Main DC cables, often with larger diameters (e.g., 16 mm² to 240 mm²), connect junction boxes to inverters, while five-core AC cables link inverters to the grid in three-phase systems.

For instance, in a factory, solar cables might power machinery, reducing operational costs by supplementing grid electricity with solar energy. USE-2 cables are often used for underground connections in grounded systems, while PV Wire is preferred for ungrounded arrays due to its superior insulation. Solar cables in these settings are like the heavy-duty pipelines of a water system, ensuring a steady flow of energy to keep operations running smoothly.

Solar cables are vital in agricultural and remote applications, where access to the grid may be limited. In farming, they power irrigation systems, lighting, and machinery, often using off-grid solar setups with battery storage. For example, solar water pumping systems use solar cables to connect panels to pumps, delivering water from wells or rivers to crops.

In remote areas, solar cables enable standalone systems for lighting and powering equipment, often requiring cables with high weather resistance (e.g., AD8 waterproof rating) to withstand moisture and temperature extremes. PV Wire with XLPE insulation is commonly used for its durability in such harsh conditions. These cables act like lifelines, bringing energy to places where traditional power lines can’t reach, empowering sustainable agriculture and remote communities.

An emerging and exciting application of solar cables is in space technology, where they connect solar panels to power satellites, spacecraft, and space exploration missions. These cables must operate in extreme conditions, including vacuum, radiation, and temperature swings from -40°C to 120°C. They transmit electricity to generate, store, and distribute power in space, making them indispensable for space missions.

For example, solar cables in a satellite might use lightweight, radiation-resistant materials to connect solar arrays to battery systems, ensuring continuous power for communication systems. Standards like ISO 4892-3 ensure these cables can endure simulated climate conditions. In space, solar cables are like the umbilical cords of a spacecraft, delivering the energy needed to explore the final frontier.

Solar cables have evolved alongside the growth of the solar industry. In the early 2000s, as solar power gained traction, standard electrical cables were often used in PV systems, leading to frequent failures due to UV exposure and temperature extremes. The introduction of PV Wire (UL 4703) in the late 2000s marked a turning point, offering specialized cables for solar applications. European standards like EN 50618, introduced in the 2010s, further advanced solar cable technology by focusing on halogen-free materials and flexibility. Today, solar cables continue to innovate, with trends like trenching for ground-mounted projects and enhanced materials for extreme environments, supporting the global shift to renewable energy.

Solar cables are more than just wires—they’re critical components that enable the efficient and safe transmission of solar energy across diverse applications. From residential rooftops to industrial power plants, agricultural fields, and even space missions, solar cables are classified and designed to meet the unique demands of each sector. By adhering to standards like UL, IEC, and RoHS, these cables ensure reliability and safety, supporting the global transition to renewable energy. Whether you’re powering a home or a satellite, choosing the right solar cable is key to harnessing the sun’s potential for a sustainable future.