Time: 2025-02-15 05:03:33 Source: Henan Province Jianyun Cable Co., Ltd.

ACSR (Aluminum Conductor Steel Reinforced) is a type of electrical conductor that is widely used in high-voltage overhead power transmission lines. It combines the strengths of two materials: aluminum for its electrical conductivity and steel for its mechanical strength. Let’s take an in-depth look at the design, benefits, applications, and standards related to ACSR cables.

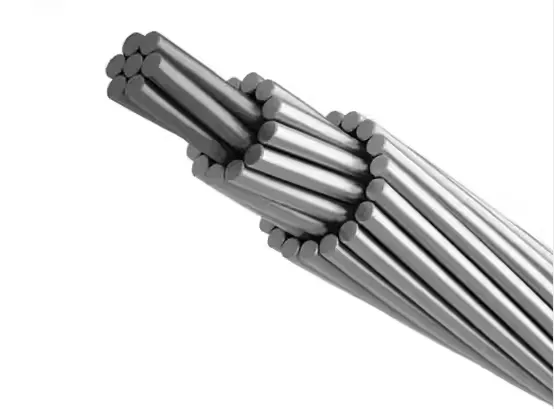

ACSR cable is a composite conductor made from aluminum and steel, where the aluminum forms the outer layer of the conductor, while the steel is used for the inner core. This design takes advantage of the electrical properties of aluminum and the mechanical properties of steel, making it ideal for power transmission lines.

Aluminum (Outer Layer):

Steel (Core):

High Strength-to-Weight Ratio: The combination of aluminum and steel in ACSR cables results in a cable with a high strength-to-weight ratio. This allows for longer spans between support towers, reducing the number of towers needed and decreasing installation costs.

Lower Sag: Due to the steel core, ACSR cables experience less sag compared to all-aluminum cables, which is crucial for long-distance power transmission, as it helps maintain the clearance between the cable and the ground.

Efficient Power Transmission: The aluminum outer layer provides excellent electrical conductivity, allowing ACSR cables to handle large amounts of electrical power transmission with minimal energy loss.

Durability and Reliability: ACSR cables are built to withstand harsh environmental conditions such as wind, ice, and UV exposure. The combination of corrosion-resistant aluminum and steel makes them particularly durable.

Cost-Effectiveness: ACSR cables offer an ideal balance of performance and cost. The use of aluminum keeps costs lower compared to other materials like copper, while the steel core ensures the cable can handle the mechanical demands of overhead power lines.

Overhead Power Transmission Lines: ACSR cables are primarily used in high-voltage overhead transmission lines due to their ability to handle large electrical currents and span long distances between towers.

Distribution Networks: They are also used in lower-voltage distribution networks that require both high electrical capacity and mechanical strength.

Crossing Rivers or Highways: ACSR’s high strength-to-weight ratio allows it to be used for spanning large distances such as rivers or highways, where long cable spans are required.

Substation Connections: In power substations, ACSR cables are used to connect various components and transmit power to different parts of the grid.

Transmission in Harsh Environments: ACSR cables are ideal for regions exposed to extreme weather conditions like ice, wind, and high temperatures, due to their mechanical strength and corrosion resistance.

ACSR cables must meet several important standards to ensure their quality and performance in power transmission systems. Key standards include:

These standards ensure that the cables have the correct balance of mechanical strength, electrical conductivity, and environmental durability.

ACSR is often compared to other types of power cables, such as:

ACSR vs AAC (All Aluminum Conductor): While both cables use aluminum for electrical conductivity, ACSR has a steel core, which provides additional strength and reduces sag. ACSR is typically used for longer spans and higher mechanical loads, whereas AAC is lighter and cheaper, making it ideal for shorter spans and lower load requirements.

ACSR vs AAAC (All Aluminum Alloy Conductor): AAAC uses aluminum alloys, which are more durable and stronger than pure aluminum, but still, ACSR offers the best combination of electrical conductivity and mechanical strength, making it more common for long-distance transmission lines.

ACSR vs Copper Conductors: Copper has better electrical conductivity than aluminum, but copper is significantly more expensive and heavier. ACSR, with its aluminum outer layer, is often preferred for high-voltage transmission lines due to its balance of cost and performance.

Susceptibility to Corrosion (Steel Core): While the aluminum outer layer is resistant to corrosion, the steel core is prone to rust over time, especially in coastal or high-humidity areas. However, galvanization of the steel core can help mitigate this issue.

Expansion and Contraction: Like all metals, ACSR cables are subject to expansion and contraction due to temperature changes. This can cause the cable to sag during hot weather or become taut in colder conditions, potentially affecting the clearance of the cable above the ground.

Installation and Maintenance: The installation of ACSR cables requires specialized equipment due to their heavy weight and large diameter. Regular maintenance is also necessary to ensure the cables are in good condition, particularly in harsh weather conditions.

Preparation: The installation of ACSR cables begins with preparing the area for the towers and supports. This includes ensuring that the cable will have enough clearance to avoid contact with the ground or other obstacles.

Transporting the Cable: ACSR cables are transported using special reels, and care must be taken to prevent damage during handling.

Stranding Process: The steel core and aluminum strands are twisted together in a process called stranding, which can be done on-site or in a manufacturing plant.

Tensioning and Suspension: During installation, the cable is tensioned and suspended from the towers using specific techniques to prevent overstretching and ensure the correct sag.

Connection to Power Grid: Once the cable is installed, it is connected to the power grid, and testing is performed to ensure proper electrical performance.

Improved Transmission Efficiency: ACSR cables reduce energy loss over long distances, providing more efficient electricity transmission.

Cost-Effectiveness: They provide a cost-effective solution for high-capacity power transmission due to the use of aluminum, which is cheaper than copper.

Longer Transmission Distance: ACSR cables allow for longer spans between transmission towers, reducing the number of towers required for a given distance, which reduces construction and maintenance costs.

ACSR (Aluminum Conductor Steel Reinforced) cables are essential components in modern electrical power transmission systems. They offer an excellent balance of electrical conductivity, mechanical strength, durability, and cost-efficiency, making them ideal for long-distance, high-voltage overhead transmission lines. Understanding the design, advantages, applications, and installation methods of ACSR cables is crucial for optimizing their use in power grids and ensuring reliable electricity delivery.

By selecting the appropriate type of conductor based on the specific needs of your transmission line (e.g., span length, environmental conditions, mechanical load), ACSR cables continue to be a cornerstone of power infrastructure worldwide.

High strength electrical wire Aluminum Conductor Steel Reinforced ACSR Conductor

Overhead Line ACSR Bare Conductor ACSR Conductor 1/0 for Overhead Applications

Convenient installation electrical power wire Aluminum Conductor Steel Reinforce

All aluminum conductor (AAC) cables are designed to provide efficient electrical