Time: 2025-03-24 12:50:14 Source: Henan Province Jianyun Cable Co., Ltd.

Aerospace electrical wiring systems (EWIS) require precise current-carrying capacity calculations to ensure safe and efficient aircraft operation. With the growing demand for reliable insulation materials, PTFE/PI (Polytetrafluoroethylene/Polyimide) composite insulated wires have gained prominence due to their high-temperature resistance and electrical stability. This article reviews a study on the current-carrying capacity of PTFE/PI insulated aerospace wires, utilizing COMSOL multiphysics simulations and experimental validation.

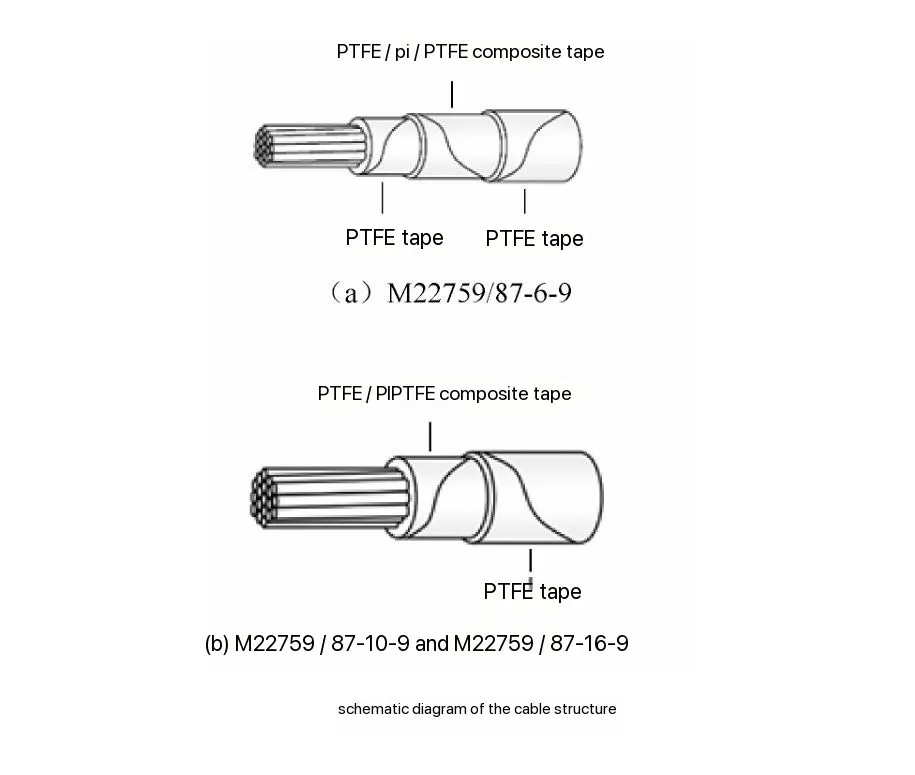

PTFE/PI insulated wires are widely used in aircraft electrical systems due to their high thermal stability, excellent dielectric properties, and lightweight flexibility, making them ideal for complex wiring configurations.

The study focused on three different wire sizes, following the SAE AS50881H:2023 standard:

| Wire Type | Conductor Diameter (mm) | Insulation Thickness (mm) | Overall Diameter (mm) | Standard |

|---|---|---|---|---|

| M22759/87-6-9 | 5.10 | 0.23 | 5.56 | SAE AS50881H:2023 |

| M22759/87-10-9 | 2.74 | 0.20 | 3.13 | SAE AS50881H:2023 |

| M22759/87-16-9 | 1.31 | 0.20 | 1.72 | SAE AS50881H:2023 |

To determine the current-carrying capacity, the study employed a multi-physics coupled model using COMSOL software. The methodology involved:

Experimental Setup

Simulation Parameters

The measured current required to reach 260°C was recorded for each wire type:

| Wire Type | Tested Current (A) | Measured Temperature (°C) |

|---|---|---|

| M22759/87-6-9 | 210.4 | 260 |

| M22759/87-10-9 | 108.1 | 260 |

| M22759/87-16-9 | 46.7 | 259 |

The actual tested values showed slight variations due to environmental factors such as air convection and measurement device placement.

The COMSOL model predicted conductor temperatures under identical electrical loads:

| Wire Type | Simulated Temperature (°C) | Experimental Temperature (°C) | SAE Standard (°C) |

|---|---|---|---|

| M22759/87-6-9 | 247.2 | 260 | 246 |

| M22759/87-10-9 | 274.6 | 260 | 271 |

| M22759/87-16-9 | 304.0 | 259 | 305 |

The simulation closely matched the SAE standard, validating its accuracy for predicting wire performance in real-world applications.

Larger diameter wires dissipate heat more efficiently, leading to lower temperature rises. Smaller wires retain more heat, resulting in higher temperatures for the same current level.

Advantages of Using COMSOL Simulations

Potential Limitations

Practical Applications

This study demonstrated that PTFE/PI composite insulated aerospace wires exhibit reliable thermal and electrical performance, with current-carrying capacities aligning with SAE AS50881H:2023 standards. COMSOL-based simulations provided accurate predictions, reducing the need for expensive experimental testing.

By leveraging advanced simulation tools, engineers can optimize wire selection to enhance the safety and efficiency of aerospace electrical systems.

Future work should focus on additional validation across different ambient temperatures and altitudes to refine the accuracy of predictive modeling.

Aerospace wires, PTFE insulation, current carrying capacity, COMSOL simulation, thermal analysis.

This article provides a clear, accessible summary of complex technical research, ensuring better understanding for industry professionals and engineers working with aerospace electrical systems.