Time: 2025-04-14 11:59:38 Source: Henan Province Jianyun Cable Co., Ltd.

Control cables are specialized electrical cables designed to transmit low-voltage signals between control units and the equipment they manage. Unlike power cables, which deliver high currents to drive motors or appliances, control cables carry signals—typically in the range of 24V to 110V—to control, monitor, or automate processes. These signals might activate a relay, adjust a motor’s speed, or send feedback from a sensor to a programmable logic controller (PLC).

The primary function of a control cable is to ensure accurate and reliable communication. For example, in a manufacturing plant, a control cable might connect a PLC to a conveyor system, sending signals to start, stop, or adjust the conveyor’s speed based on production needs. The cable must transmit these signals without distortion or interference, even in noisy industrial environments where electromagnetic interference (EMI) is common.

Think of control cables as the nervous system of a machine: just as nerves relay signals from the brain to the body, control cables carry instructions from a control unit to the equipment, ensuring everything operates in harmony. Their ability to deliver precise signals makes them essential in automation, robotics, and industrial control systems.

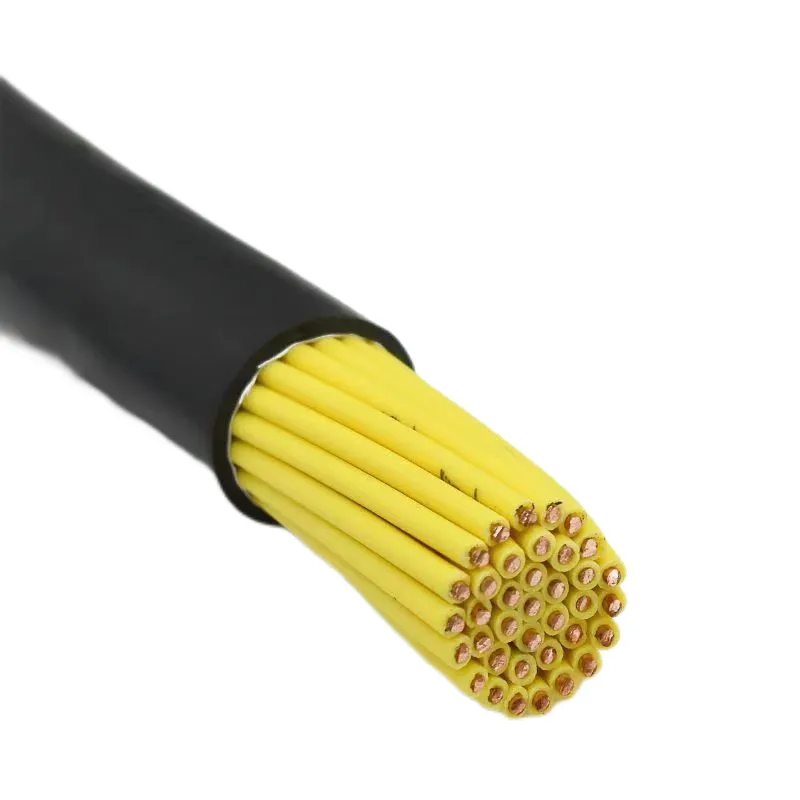

Control cables are engineered for reliability and precision, with a multi-layered design that protects the signal integrity while withstanding harsh conditions. A typical control cable consists of several components, each serving a specific purpose.

The design of a control cable is like a well-orchestrated symphony: each layer plays a role in ensuring the signals (the music) are delivered clearly and without interruption. For instance, a control cable used in a robotic arm might have 12 conductors, each insulated and shielded, all wrapped in a flexible PUR jacket to withstand constant movement.

Control cables are used in a wide range of industries where precise control and automation are required. Their ability to transmit signals reliably makes them indispensable in both industrial and commercial settings.

Each application demands a control cable tailored to its environment. For example, a cable in a marine setting might need a halogen-free jacket to prevent toxic fumes in case of fire, while one in a factory might prioritize flexibility for frequent movement. Choosing the right cable is like picking the right tool for a job—it ensures everything runs smoothly and safely.

The conductors and insulation in control cables are chosen to ensure reliable signal transmission, flexibility, and durability, especially in demanding environments.

Conductors: Control cables typically use stranded copper conductors due to their flexibility and excellent conductivity. Stranded conductors, made of multiple thin copper strands twisted together, are ideal for applications involving frequent bending, such as in robotic systems. The conductors are usually small—ranging from 0.5 mm² to 2.5 mm²—since control cables handle low currents (e.g., 1A to 5A). In some cases, tinned copper is used to enhance corrosion resistance, especially in marine or humid environments.

Insulation: The insulation must prevent signal interference between conductors while withstanding environmental stresses. Common materials include:

The choice of conductor and insulation is a balancing act between performance and practicality. For instance, a control cable in a data center might use PE insulation for better signal clarity, while one in a factory might use PVC for cost-effectiveness. It’s like choosing the right fabric for a jacket—each material suits a specific climate and purpose.

Shielding is a critical feature in many control cables, especially those used in environments with high levels of electromagnetic interference (EMI). EMI, often caused by nearby motors, transformers, or radio signals, can distort the low-voltage signals carried by control cables, leading to errors or system failures.

Types of Shielding:

Shielding works by creating a Faraday cage around the conductors, blocking external electromagnetic fields and preventing signal distortion. For example, a control cable connecting a PLC to a motor in a factory might use braided shielding to ensure the motor’s electrical noise doesn’t interfere with the control signals. Without shielding, the system might misinterpret the signals, causing the motor to malfunction.

Shielding is like noise-canceling headphones for a control cable—it filters out the “background noise” of EMI, ensuring the signal (the music) comes through loud and clear. In applications where precision is critical, such as medical equipment or aerospace systems, shielding is non-negotiable.

Control cables are subject to rigorous standards to ensure they perform reliably and safely in their intended applications. These standards, set by organizations like the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and the National Electrical Code (NEC), cover everything from electrical performance to fire safety.

Certified control cables often bear markings like “UL Listed” or “IEC Compliant” on their jackets, indicating they’ve passed these tests. For example, a UL-listed control cable might be tested to withstand 300V without breaking down, ensuring it’s safe for its intended use. Choosing a certified cable is like buying a certified helmet—it’s a guarantee of safety and reliability you can trust.

Proper installation and maintenance of control cables are crucial to ensure reliable signal transmission, safety, and longevity. Poor installation can lead to signal loss, equipment malfunctions, or even safety hazards, especially in industrial environments.

Installation Tips:

Maintenance Tips:

Proper installation and maintenance are like regular tune-ups for a car—they keep the system running smoothly and prevent breakdowns. In critical applications, such as railway signaling or medical equipment, following these practices is essential to ensure safety and reliability.

The history of control cables is tied to the rise of automation in the 20th century. Early control systems in the 1900s used simple wires with basic insulation, often prone to interference and failure. The development of shielded cables in the mid-20th century, driven by the growth of industrial automation and telecommunications, marked a turning point. The introduction of synthetic insulation materials like PVC and PE in the 1950s improved durability and signal clarity. Today, advancements like halogen-free materials and enhanced shielding reflect a focus on safety and performance, ensuring control cables can meet the demands of modern automation systems.

Control cables may operate behind the scenes, but their role in automation and control systems is nothing short of critical. From their multi-layered design to their diverse applications, these cables are engineered to deliver precise signals in the most challenging environments. By understanding their conductors, insulation, shielding, and standards, we can appreciate the precision and reliability they bring to industries and everyday life. Whether they’re managing a factory assembly line or ensuring a train runs on time, control cables are the precision conductors that keep our automated world in motion.