Time: 2025-03-14 16:14:12 Source: Henan Province Jianyun Cable Co., Ltd.

Cross-linked polyethylene (XLPE) is widely used as insulation material in high-voltage power cables due to its excellent electrical performance, mechanical strength, and resistance to environmental stress cracking. However, thermal oxidative aging under high temperatures and oxygen exposure significantly affects its lifespan and performance.

This study aims to analyze the molecular structure changes, thermal behavior, oxidation resistance, microstructure, and electrical properties of XLPE through accelerated aging tests. The research also estimates the thermal oxidative aging lifespan at 90°C to be approximately 68.2 years.

| Material | Source | Purpose |

|---|---|---|

| Low-density polyethylene (LDPE) | Yangzi Petrochemical | Base material |

| Peroxide crosslinking agent (DCP) | Jiangsu Daoming Chemical Co. | Crosslinking agent |

| Antioxidant 1010 | BASF | Main antioxidant |

| Antioxidant 412s | Kooria | Auxiliary antioxidant |

| Nano-SiO₂ filler | Guangzhou Hongwu Materials Co. | Nano filler for reinforcement |

| Equipment | Function |

|---|---|

| Fourier Transform Infrared Spectroscopy (FTIR) | Molecular structure analysis |

| Differential Scanning Calorimetry (DSC) | Melting and crystallization behavior |

| Thermogravimetric Analysis (TGA) | Thermal stability |

| Scanning Electron Microscope (SEM) | Microstructure observation |

| High Insulation Resistance Tester | Electrical performance analysis |

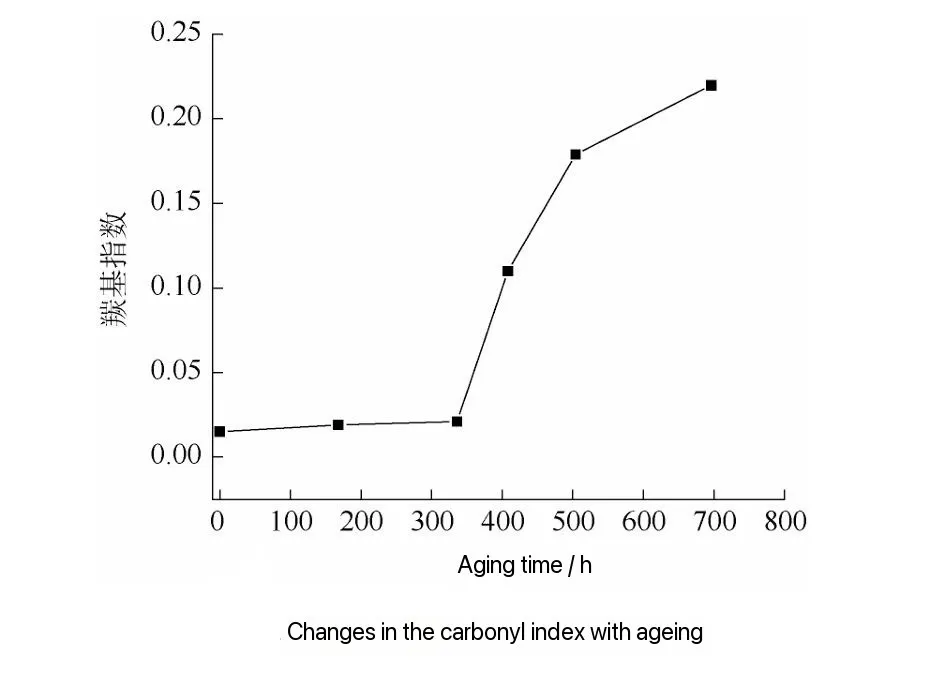

During thermal oxidative aging, oxidation-induced chemical bonds (C=O and C-O-C) increase, while methylene (CH₂) vibration intensity decreases.

| Aging Time (Hours) | Carbonyl Index |

|---|---|

| 0 | 0.12 |

| 336 | 0.35 |

| 504 | 0.67 |

| 696 | 1.12 |

➡ Conclusion: The formation of carbonyl groups indicates polymer chain breakage and oxidation degradation during aging.

With prolonged aging, the melting temperature gradually decreases, and the crystallization peak shifts to lower temperatures, indicating reduced molecular chain regularity and incomplete crystallization.

| Aging Time (Hours) | Melting Point (°C) | Crystallization Temperature (°C) |

|---|---|---|

| 0 | 129.5 | 116.2 |

| 336 | 127.8 | 114.5 |

| 504 | 125.2 | 110.8 |

| 696 | 121.9 | 108.5 |

➡ Conclusion: Thermal oxidative aging damages the crystalline structure and reduces the thermal stability of XLPE.

OIT (Oxidation Induction Time) gradually shortens as the antioxidant depletes, indicating worsening oxidative stability.

| Aging Time (Hours) | OIT (Minutes) |

|---|---|

| 0 | >60 |

| 72 | 31.2 |

| 216 | 16.1 |

| 504 | 6.1 |

➡ Conclusion: Antioxidant depletion accelerates oxidative degradation of XLPE insulation.

| Aging Time | Microstructure Observation |

|---|---|

| 0 Hours | Smooth, compact surface |

| 336 Hours | Minor cracks and microvoids |

| 504 Hours | Significant surface cracks and oxidation particles |

| 696 Hours | Severe surface damage and erosion |

➡ Conclusion: Prolonged aging leads to microcracks, surface roughness, and severe material degradation.

| Aging Time (Hours) | Dielectric Constant | Volume Resistivity (Ω·cm) |

|---|---|---|

| 0 | 2.2 | 1.0 × 10¹⁷ |

| 336 | 2.8 | 5.6 × 10¹⁶ |

| 504 | 3.5 | 1.0 × 10¹⁵ |

➡ Conclusion: The increase in polar groups (C=O and C-O-C) after oxidation increases the dielectric constant and reduces the electrical insulation performance.

Using thermogravimetric analysis (TGA) and the Ozawa method, the activation energy (Ea) of XLPE was calculated to be 119 kJ/mol.

By applying the Arrhenius equation, the thermal oxidative aging lifespan at 90°C is estimated at 68.2 years, meeting the service life requirements for nuclear-grade cables (60 years).

| Performance Indicator | Change After Aging |

|---|---|

| Mechanical Strength | Decreases by 45% |

| Electrical Insulation | Drops by 90% |

| Thermal Stability | Reduced crystallinity |

| Surface Morphology | Severe surface cracks |

Thermal oxidative aging of XLPE insulation is driven by antioxidant depletion and polymer chain breakage, leading to surface damage and electrical performance loss.

The carbonyl index, melting temperature, and OIT are effective indicators for quickly assessing aging levels.

The activation energy of 119 kJ/mol allows for accurate lifespan prediction, with an estimated lifespan of 68.2 years at 90°C.