Time: 2025-04-14 09:37:35 Source: Henan Province Jianyun Cable Co., Ltd.

Electric wires are conductive pathways designed to transmit electrical current from a power source to a device or system. At their simplest, they consist of a metal core—called the conductor—surrounded by a protective layer of insulation. The conductor allows electrons to flow, creating an electrical circuit, while the insulation prevents unwanted contact with other wires, surfaces, or people, ensuring the current stays on its intended path.

The working principle of an electric wire is rooted in basic physics: when a voltage is applied across the wire, electrons move through the conductor, generating an electric current. The efficiency of this process depends on the conductor’s material, the wire’s thickness, and the quality of its insulation. For example, a wire powering a ceiling fan in your home completes a circuit from the electrical panel to the fan, allowing it to spin. It’s a bit like a highway for electrons, with the wire acting as the road and the insulation as guardrails to keep the traffic (current) safe and directed.

Electric wires vary widely in size, design, and application, from the thin strands in a USB cable to the thick cables used in power grids. Regardless of their purpose, their fundamental job remains the same: to deliver electricity reliably and safely.

The materials used in electric wires are carefully chosen to balance conductivity, durability, and cost. The two main components of a wire—the conductor and the insulation—each rely on specific materials to perform their roles effectively.

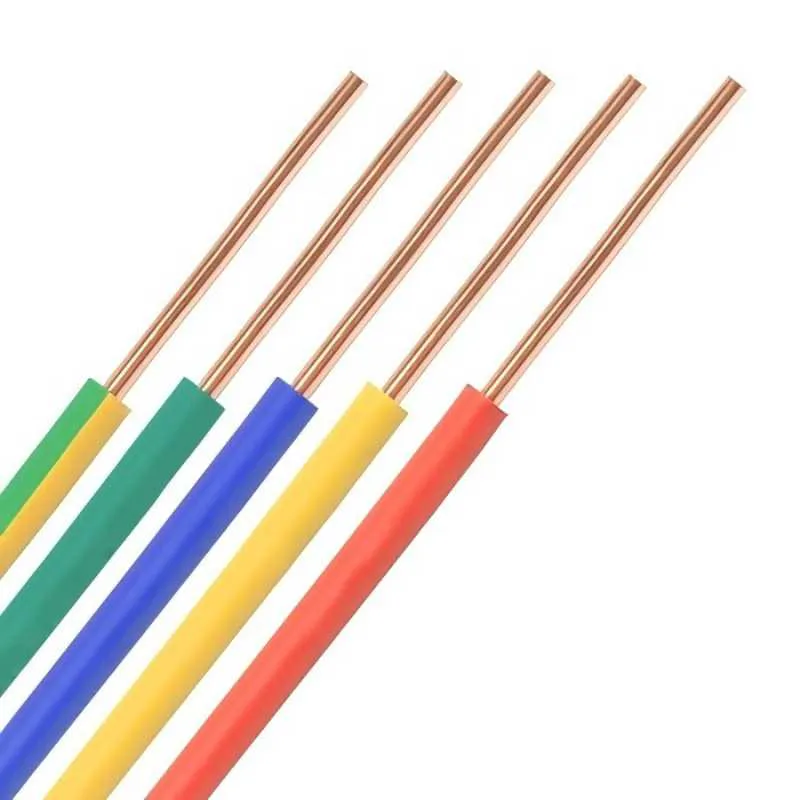

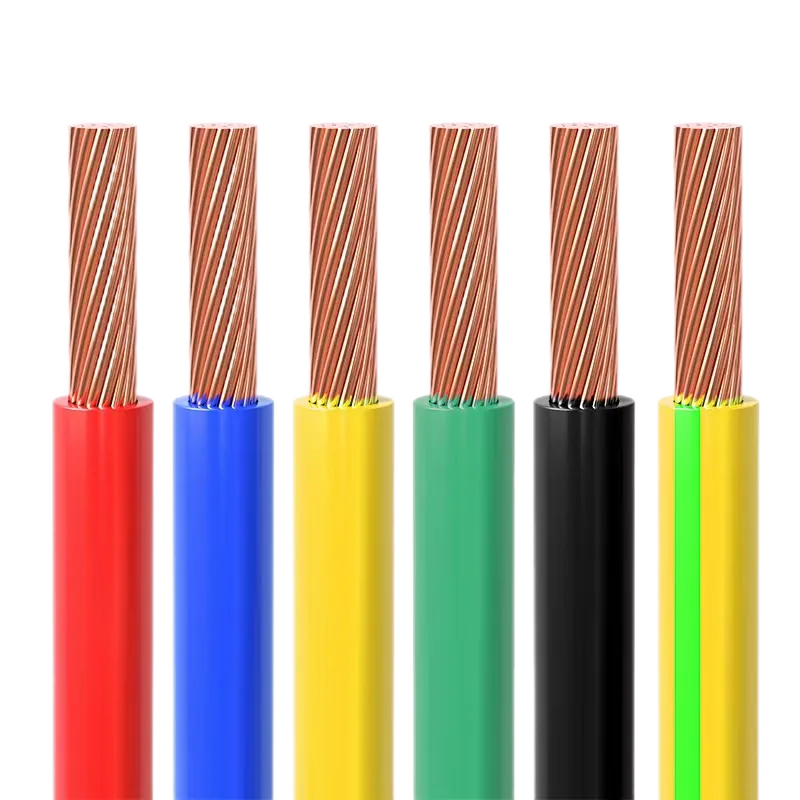

Conductors: The conductor is the wire’s core, responsible for carrying electrical current. The most common materials are:

Insulation: The insulation surrounds the conductor, preventing electrical leakage and protecting against environmental factors. Common insulation materials include:

Some wires also include additional layers, like a metallic shield to reduce electromagnetic interference or a tough outer jacket for extra protection. The choice of materials is like picking ingredients for a recipe—each one plays a role in the wire’s overall performance, ensuring it can handle the demands of its specific application.

Electric wires come in a variety of types, each designed for specific purposes. Knowing the differences helps ensure you’re using the right wire for the job, whether you’re wiring a home or setting up a telecommunications network.

Choosing the wrong wire type can lead to inefficiency or safety hazards. For example, using NM-B wire outdoors without proper protection can cause the insulation to degrade due to moisture, leading to potential shorts. It’s like wearing flip-flops to hike a mountain—you need the right gear for the terrain.

Wire gauge refers to the thickness of the wire’s conductor, typically measured using the American Wire Gauge (AWG) system in the U.S. The AWG number inversely correlates with the wire’s diameter: a smaller number (e.g., 10 AWG) indicates a thicker wire, while a larger number (e.g., 18 AWG) means a thinner wire.

The gauge directly affects the wire’s ability to carry current and its resistance to heat. Thicker wires (lower AWG) can handle more current with less resistance, making them suitable for high-power applications. For instance, a 12 AWG wire can safely carry 20 amps, enough for a 2400W appliance at 120V. Thinner wires (higher AWG) are better for low-power devices, like a 24 AWG wire in an Ethernet cable.

Using the wrong gauge can be dangerous. A wire too thin for the load will overheat, potentially melting the insulation or starting a fire, while an overly thick wire is unnecessarily expensive and cumbersome. For example, running a heavy-duty air conditioner on a 16 AWG wire (rated for 13 amps) instead of a 10 AWG wire (rated for 30 amps) could lead to disaster. Think of wire gauge like the size of a water pipe: too small, and the pressure builds up dangerously; too large, and it’s a waste of resources.

Insulation is the protective layer that surrounds the conductor in an electric wire, and it’s absolutely critical for safety and performance. Without insulation, wires would be prone to short circuits, electrical shocks, and fires due to unintended contact between conductors or with external surfaces like walls or human skin.

Insulation serves several key purposes:

Insulation materials vary depending on the wire’s use. For example, PVC is common for indoor wiring due to its affordability and durability, while rubber is used in flexible cords that need to withstand frequent bending. In high-voltage applications, materials like XLPE are chosen for their ability to handle extreme temperatures. Insulation is like a raincoat for the wire—it keeps the “rain” (external hazards) out, ensuring the current flows safely to its destination.

Electric wires are designed with multiple safety features to protect both the wire itself and the people using it. These features are governed by strict standards set by organizations like the National Electrical Code (NEC), the Underwriters Laboratories (UL), and the International Electrotechnical Commission (IEC).

Key Safety Features:

These features work together like a safety net, catching potential hazards before they become disasters. For instance, a properly grounded wire can prevent a lethal shock if an appliance malfunctions, while fire-resistant insulation can stop a small spark from turning into a house fire. Always choose wires with these safety features to ensure peace of mind.

Electric wires, like any infrastructure, require regular maintenance to ensure they remain safe and functional. With proper care, wires can last decades, but neglect can lead to dangerous failures. Here’s how to maintain them and recognize when replacement is necessary.

Maintenance Tips:

When to Replace: Wires typically last 30–50 years in residential settings, but certain conditions can shorten their lifespan. Replace wires if you notice:

Replacing old wires can be costly, but it’s a critical investment in safety. It’s like replacing worn-out tires on a car—waiting too long risks a blowout, but timely replacement keeps you safe on the road.

The history of electric wires mirrors the evolution of electricity itself. In the early 1800s, wires were often bare copper, posing significant risks of shocks and fires. The 1840s brought a breakthrough with the use of gutta-percha (a natural rubber) as insulation, followed by vulcanized rubber in the late 19th century. By the 1920s, the introduction of PVC revolutionized wire manufacturing, making insulation cheaper and more durable. Today, advancements like halogen-free insulation and eco-friendly materials continue to improve the safety and sustainability of electric wires, ensuring they meet the demands of our increasingly electrified world.

Electric wires may be small and often hidden, but their role in our lives is monumental. They form the intricate network that powers our homes, offices, and industries, delivering electricity with precision and reliability. From the materials used in their construction to the safety features that protect us, every aspect of an electric wire is a testament to human ingenuity. By understanding their types, gauges, insulation, and maintenance needs, we can make informed choices to ensure our electrical systems remain safe and efficient. So, the next time you turn on a light or charge your phone, take a moment to appreciate the humble electric wire—the silent force keeping our world connected.