Time: 2025-04-14 12:20:31 Source: Henan Province Jianyun Cable Co., Ltd.

As the world embraces sustainable practices and recyclable materials, polypropylene (PP) has emerged as a promising candidate to replace traditional cross-linked polyethylene (XLPE) in cable insulation. PP offers excellent thermal and electrical properties, higher temperature resistance, and environmental recyclability. However, its brittle nature, poor impact resistance, and high flexural modulus pose challenges for large-scale adoption in power cables.

This article presents a detailed analysis of how five different elastomers affect the mechanical and electrical properties of PP when used as toughening agents. The research offers actionable insights for cable manufacturers aiming to develop eco-friendly, mechanically stable, and high-performance insulation materials.

Traditional XLPE insulation has drawbacks including high energy consumption during crosslinking, release of volatile byproducts, and being non-recyclable. In contrast, PP is recyclable and aligns with green manufacturing goals. Yet, it needs modification to overcome limitations in flexibility and durability.

Elastomer blending is a proven method to enhance PP’s toughness. But selecting the right elastomer is critical because some may compromise dielectric performance, especially under elevated temperatures.

| Elastomer | Type | Glass Transition Temp (°C) | Flexural Modulus (MPa) |

|---|---|---|---|

| CA10A | Propylene-based | -25 | 90.0 |

| 2032PM | Ethylene-propylene | -50 | 10.8 |

| CA60A | Propylene-based | -25 | 80.0 |

| YH-06 | Styrene-based | <-60 | 4.3 |

| C3080 | Ethylene-octene | -56 | 8.8 |

All blends were composed of 80 parts PP and 20 parts elastomer. Melt blending was done using a twin-screw extruder at 180°C, followed by molding and testing.

| Material | Failure Samples (out of 30) |

|---|---|

| Pure PP | 30 |

| PP / CA10A | 6 |

| PP / 2032PM | 0 |

| PP / CA60A | 14 |

| PP / YH-06 | 0 |

| PP / C3080 | 0 |

| Material | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|

| Pure PP | 20.9 | 705 |

| PP / CA10A | 20.3 | 689 |

| PP / 2032PM | 16.8 | 578 |

| PP / CA60A | 19.6 | 657 |

| PP / YH-06 | 12.8 | 426 |

| PP / C3080 | 16.6 | 559 |

| Material | Dielectric Constant (90°C) | Dielectric Loss (×10⁻⁴) |

|---|---|---|

| Pure PP | 2.61 | 3.11 |

| PP / CA10A | 2.37 | 4.85 |

| PP / 2032PM | 2.53 | 51.10 |

| PP / CA60A | 2.52 | 5.28 |

| PP / YH-06 | 2.36 | 2.65 |

| PP / C3080 | 2.40 | 53.10 |

| Material | Melting Enthalpy (J/g) | Crystallinity (%) |

|---|---|---|

| Pure PP | 65.89 | 31.52 |

| PP / CA10A | 61.60 | 29.47 |

| PP / 2032PM | 54.88 | 26.25 |

| PP / CA60A | 60.25 | 28.82 |

| PP / YH-06 | 57.19 | 27.36 |

| PP / C3080 | 58.39 | 27.93 |

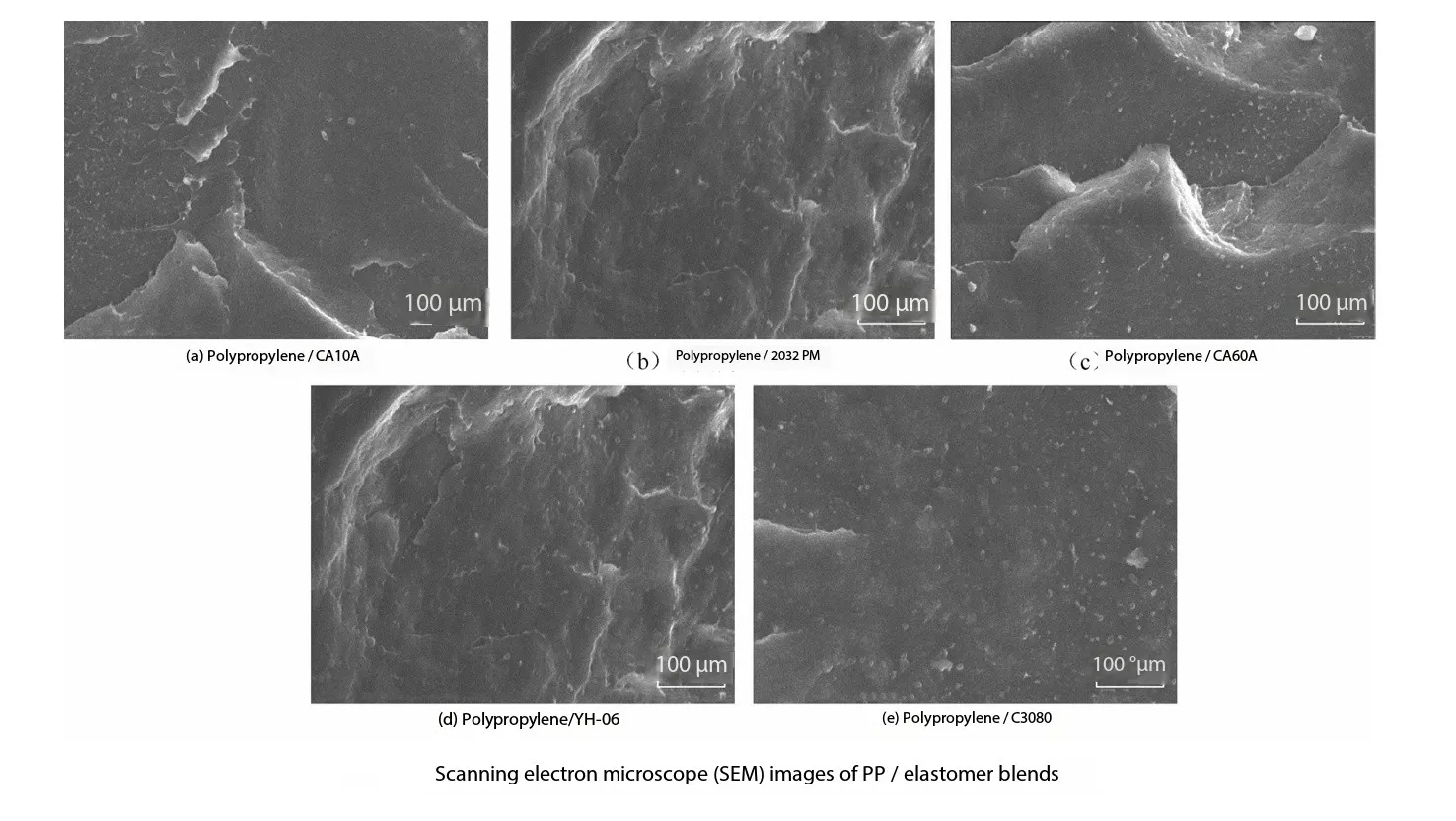

SEM images show uniform dispersion and “sea-island” structures, confirming excellent compatibility between PP and YH-06, 2032PM, and C3080. Stress whitening bands reveal impact resistance performance. YH-06 showed minimal whitening, confirming optimal energy absorption.

All tested elastomers improve PP’s toughness. YH-06 emerged as the most balanced in mechanical and dielectric performance, while CA10A and CA60A offer cost-effective benefits. C3080 and 2032PM should be avoided for high-voltage applications due to high dielectric losses.

Polypropylene (PP), Elastomer Blending, Toughening Modifier, Dielectric Loss, Cable Insulation Materials, Mechanical Flexibility, Crystallinity, Environmental Cable Materials