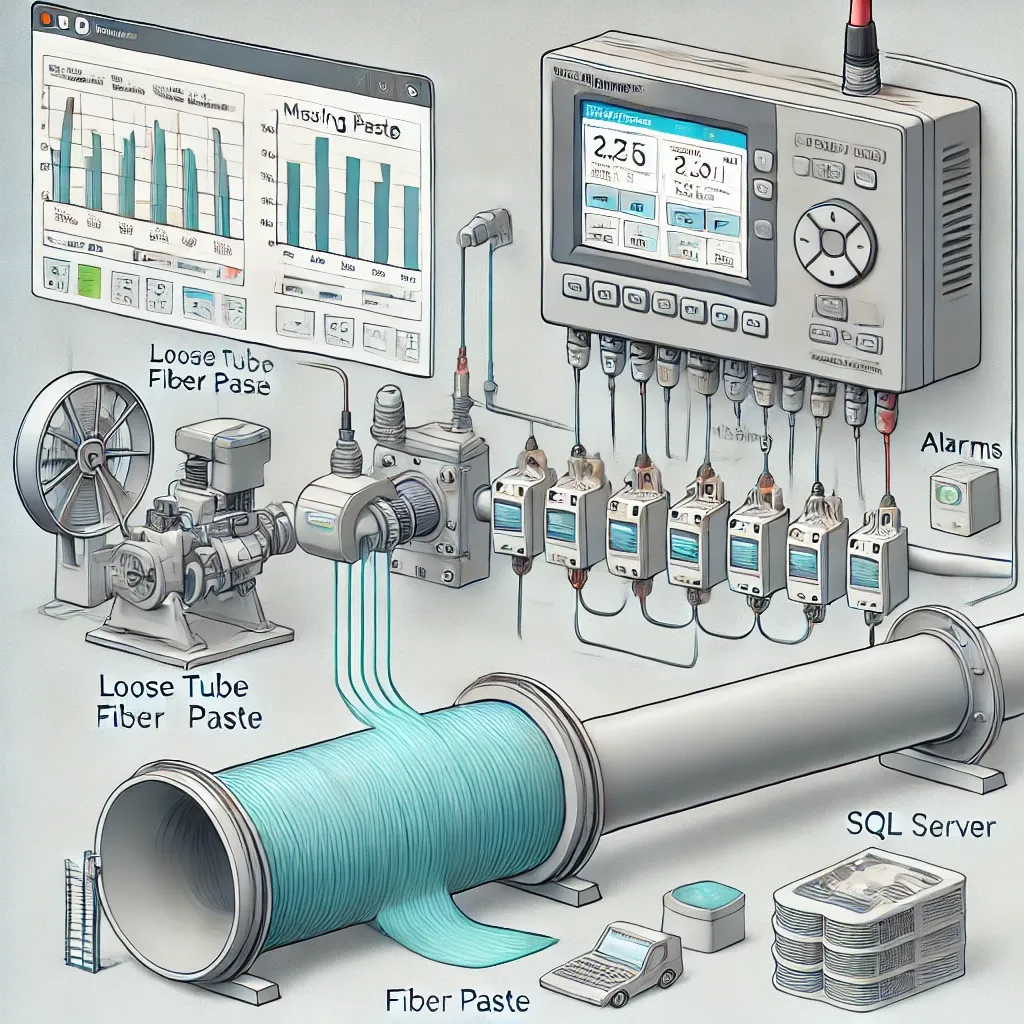

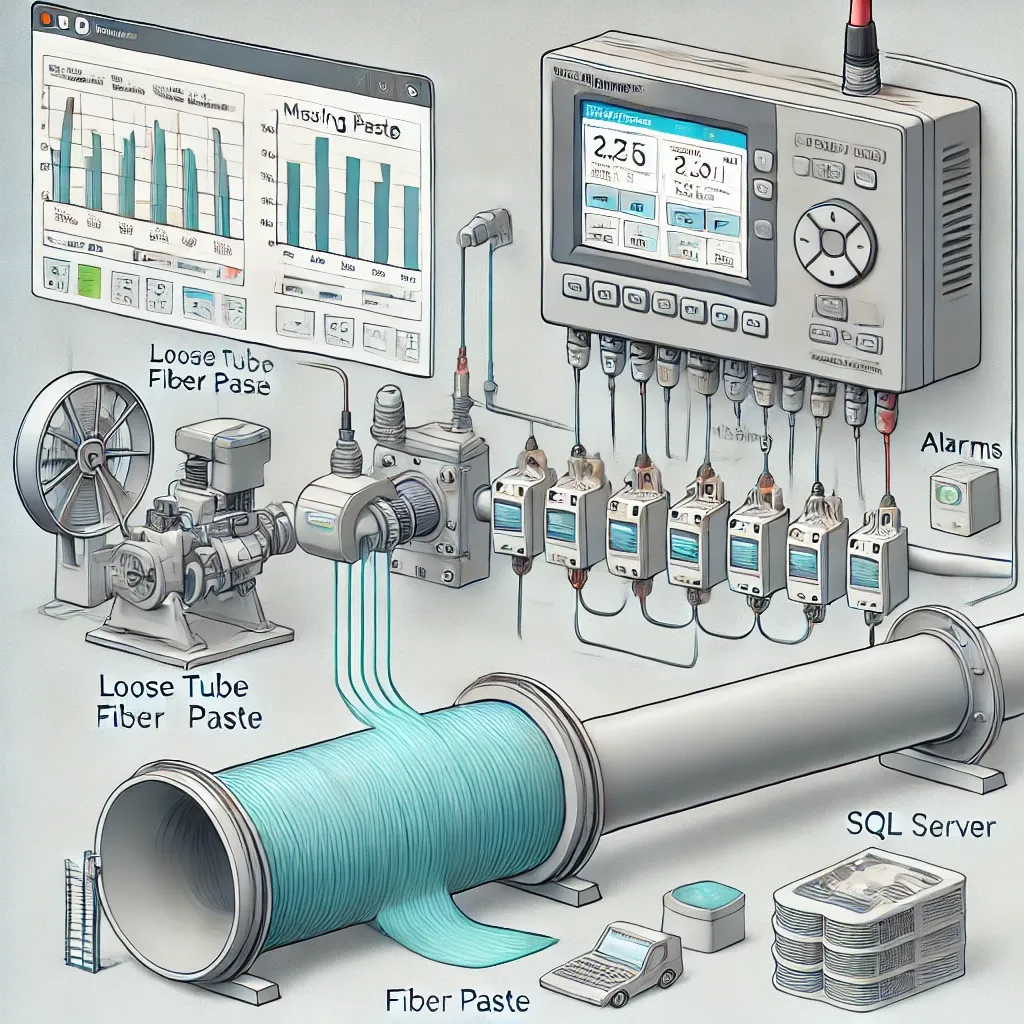

Flow Measurement Control System for Loose Tube Fiber Paste Based on PLC and Database Operations

Time: 2025-03-17 15:43:39

Source: Henan Province Jianyun Cable Co., Ltd.

Introduction

In the production of loose tube optical cables, fiber paste is essential for protecting optical fibers from moisture and mechanical stress. Traditional manual filling methods lead to inconsistent paste usage, higher material costs, and quality risks. This study introduces a PLC-based flow measurement control system, combined with database operations, to achieve real-time monitoring and closed-loop control of fiber paste flow.

1. System Design and Structure

1.1 Key Components

The system consists of:

-

Clamp-type ultrasonic flow sensors for measuring flow rate and time.

-

Siemens S7-300 PLC for data processing and control.

-

SQL Server database for data storage and analysis.

-

SCADA system (Supervisory Control and Data Acquisition) for real-time monitoring and alarm display.

1.2 Working Principle

Using ultrasonic transmission time difference measurement, the system calculates flow rate as:

Q=Δt×r2×c22LQ = \frac{\Delta t \times r^2 \times c^2}{2L}Q=2LΔt×r2×c2

where:

-

QQQ: Instantaneous flow

-

Δt\Delta tΔt: Time difference between forward and reverse ultrasonic signals

-

rrr: Pipe radius

-

ccc: Speed of sound in fiber paste

-

LLL: Distance between sensors

2. Control System Architecture

|

Module

|

Function

|

|

Ultrasonic Flow Sensor

|

Measures real-time flow

|

|

PLC (Siemens S7-300)

|

Data acquisition and control

|

|

SQL Database

|

Data storage and analysis

|

|

SCADA Interface

|

Alarm monitoring and data visualization

|

3. Real-Time Flow Monitoring and Control

3.1 Instantaneous Flow Monitoring

-

Detects flow rate in real-time

-

Provides instant alarms when paste is missing

-

Adjusts fiber paste pump speed to maintain consistency

3.2 Cumulative Flow Calculation

-

Tracks total paste usage for each tube

-

Supports cost analysis and material optimization

4. Database Operations and Data Analysis

-

Real-time data is uploaded to SQL Server

-

Allows historical data tracking for quality management

-

Supports production cost analysis and defect traceability

5. Results and Performance Improvement

|

Parameter

|

Before System Implementation

|

After System Implementation

|

|

Average Paste Consumption

|

1.09 L/km

|

0.90 L/km

|

|

Consumption Reduction

|

-

|

17%

|

|

Production Quality Stability

|

Unstable

|

Highly Stable

|

6. Conclusion

-

The PLC-based fiber paste flow measurement control system ensures real-time monitoring and closed-loop control.

-

It reduces paste consumption by 17%, saving raw materials and costs.

-

The integration of the database and production management system allows for data-driven quality management and defect traceability.

7. Keywords

-

Fiber Paste Flow Control

-

PLC-Based Automation System

-

Real-Time Monitoring and Alarm

-

SQL Database Data Analysis

-

Loose Tube Optical Cable Manufacturing

8. References

-

Wu Shuhong et al. (2024). Flow Measurement Control System for Loose Tube Fiber Paste Based on PLC and Database Operations. Wire & Cable, No.6, 2024. DOI: 10.16105/j.dxdl.1672-6901.202406012

-

GB/T 19666-2019 - General Rules for Optical Cable Manufacturing

-

IEC 61158 - Industrial Communication Networks