Time: 2025-03-23 01:12:20 Source: Henan Province Jianyun Cable Co., Ltd.

As power systems continue to evolve, the demand for high fire-resistant cables has increased significantly. Fire-resistant cables play a crucial role in ensuring the safety of electrical installations, especially in densely populated buildings. This article reviews the research on the fire safety performance of flexible fire-resistant cables, comparing testing standards, fire resistance characteristics, and offering insights into improving cable design for enhanced safety.

Fire-resistant cables are categorized based on their insulation and sheathing materials. The most common types include:

Rigid fire-resistant cables (BTTZ): Utilize magnesium oxide insulation, offering excellent fire resistance but high installation costs.

Flexible fire-resistant cables (BBTRZ, BTLY, YTTW, RTTZ): Insulated with mica tape and further protected by non-metallic or metallic sheaths.

| Cable Type | Insulation | Sheath | Voltage Rating | Standard |

|---|---|---|---|---|

| N-YJV | Mica tape | Non-metallic | 0.6/1 kV | GB/T 19666-2019 |

| BBTRZ | Mica tape | Non-metallic | 0.6/1 kV | Q/GZNY 11-2020 |

| BTLY | Mica tape | Aluminum + non-metallic | 0.6/1 kV | T/GDWCA 0062-2020 |

| YTTW | Mica tape | Copper | 0.6/1 kV | JG/T 313-2014 |

| RTTZ | Mica tape | Copper | 450/750V & 0.6/1 kV | GB/T 34926-2017 |

| BTTZ | Magnesium oxide | Copper | 750V | GB/T 13033.1-2007 |

Each cable type follows specific fire resistance testing standards, impacting its performance in real-world applications.

Fire resistance testing evaluates a cable’s ability to withstand extreme conditions while maintaining electrical integrity. Major testing methods include:

| Standard | Test Type | Applicable Voltage | Temperature (°C) | Duration (min) | Additional Factors |

|---|---|---|---|---|---|

| GB/T 19666-2019 | Pure fire exposure | ≤1 kV | 750 | 90 | None |

| Fire + mechanical impact | ≤1 kV | 830 | 120 | Mechanical shocks | |

| Fire + mechanical impact + water spray | ≤1 kV | 830 | 120 | Water spray in last 15 min | |

| BS 6387:2013 | Fire only | ≤1 kV, Ø ≤20mm | 950 | 180 | None |

| Fire + water | ≤1 kV, Ø ≤20mm | 650 | 30 | 15 min fire, 15 min fire + water | |

| Fire + impact | ≤1 kV, Ø ≤20mm | 950 | 15 | Mechanical impact | |

| BS 8491:2008 | Fire + mechanical impact + water spray | ≤1 kV, Ø >20mm | 830-870 | 120 | Final 5 min with water spray |

The differences in testing standards can lead to inconsistencies in cable selection for fire-critical applications.

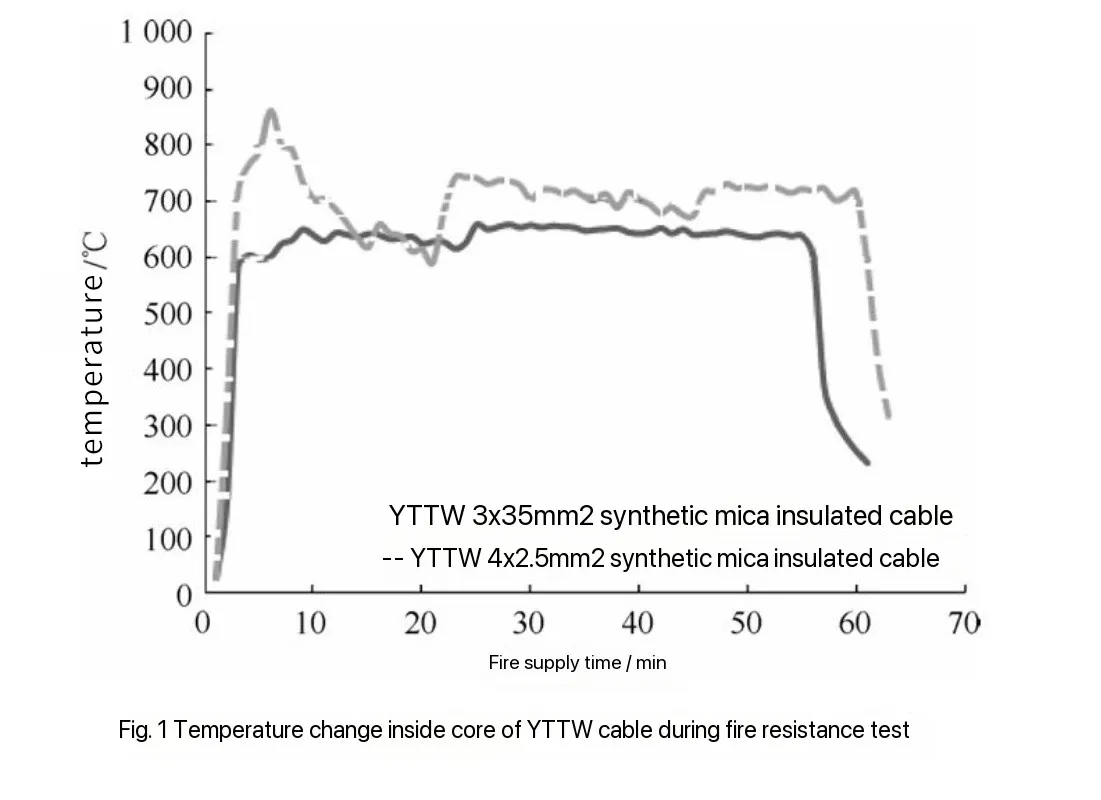

Experiments on YTTW cables (4×2.5 mm² and 3×35 mm²) under 950-1000°C revealed that:

Small-section cables experience rapid temperature rises, reaching 700°C within 8 minutes, increasing brittleness.

Large-section cables maintain a lower, more stable temperature (~650°C).

Implication: Insulating materials must maintain integrity at temperatures up to 800°C.

Mica tape and ceramic silicone were tested for electrical insulation:

| Temperature (°C) | Mica Tape (Ω) | Ceramic Silicone (Ω) |

|---|---|---|

| 150 | 2.2×10¹² | 3.3×10⁷ |

| 400 | 3.8×10⁹ | 2.5×10⁷ |

| 600 | 1.4×10⁸ | 1.5×10⁵ |

| 800 | 727 | 3.6×10³ |

| 900 | 21 | 183 |

Implication: Mica tape experiences insulation failure between 700-800°C, requiring additional protective layers.

High-temperature exposure (950-1000°C) on 1.5m and 100m YTTW cables showed:

Shorter cables had increased internal pressure (0.50 MPa), leading to sheath rupture at 9.5 minutes.

Longer cables maintained stable internal pressure.

Implication: Pressure management must be considered in flexible fire-resistant cable designs.

Tests on different cable types at 706A revealed significant variation in heat dissipation:

| Cable Type | Maximum Conductor Temperature (°C) |

|---|---|

| N-YJV | 91.4 |

| BBTRZ | 71.7 |

| BTLY | 62.7 |

| YTTW | 131.7 |

| RTTZ | 131.7 |

Implication: Different structures and materials impact heat dissipation, affecting the actual current-carrying capacity.

The external surface temperature after full-load operation for 1 hour was:

| Cable Type | Surface Temperature (°C) |

|---|---|

| N-YJV | 58 |

| BBTRZ | 73 |

| BTLY | 78 |

| YTTW | 69 |

| RTTZ | 69 |

Implication: High sheath temperatures pose risks of burns and require additional insulation or separation measures.

Based on experimental findings, several design improvements are suggested:

Enhance Insulation Material: Improve mica tape and ceramic silicone insulation to withstand temperatures beyond 800°C.

Optimize Protective Layers: Introduce thermal barriers to reduce temperature spikes in cable cores.

Improve Pressure Venting: Ensure long cables have ventilation pathways to prevent pressure buildup.

Increase Heat Dissipation: Use materials with better thermal conductivity to enhance cooling efficiency.

Implement Standardized Testing: Adopt stricter international standards (e.g., BS 8491:2008) for consistent product performance.

The fire safety performance of flexible fire-resistant cables is influenced by insulation integrity, conductor heating, and internal pressure variations. Future developments should focus on enhancing insulation materials and improving testing methodologies. Ensuring consistency across different standards will be key to increasing safety in high-risk electrical installations.

By addressing these factors, manufacturers can produce more reliable fire-resistant cables, helping to prevent electrical failures in fire-prone environments.

Flexible fire-resistant cables, fire safety, insulation resistance, temperature stability, fire resistance testing.

Xiong, X., Peng, L., Qiu, X. (2024). Research on Fire Safety Performance of Flexible Fire-Resistant Cables. Wire & Cable, No. 5, 2024.

GB/T 19666-2019: General Rules for Flame Retardant and Fire-Resistant Cables.

BS 6387:2013: Performance Requirements for Fire-Resistant Electrical Cables.

BS 8491:2008: Fire Resistance Tests for Large Diameter Cables.