Time: 2025-03-04 13:50:51 Source: Henan Province Jianyun Cable Co., Ltd.

Hook‑up wire (often written as “hookup wire”) is a generic term for pre‑insulated, flexible electrical wire used to connect components in electronic circuits, prototyping boards, appliances, and even automotive wiring. Known for its ease of use and availability in multiple colors and gauges, hook‑up wire is essential for both hobbyists and professional electrical engineers.

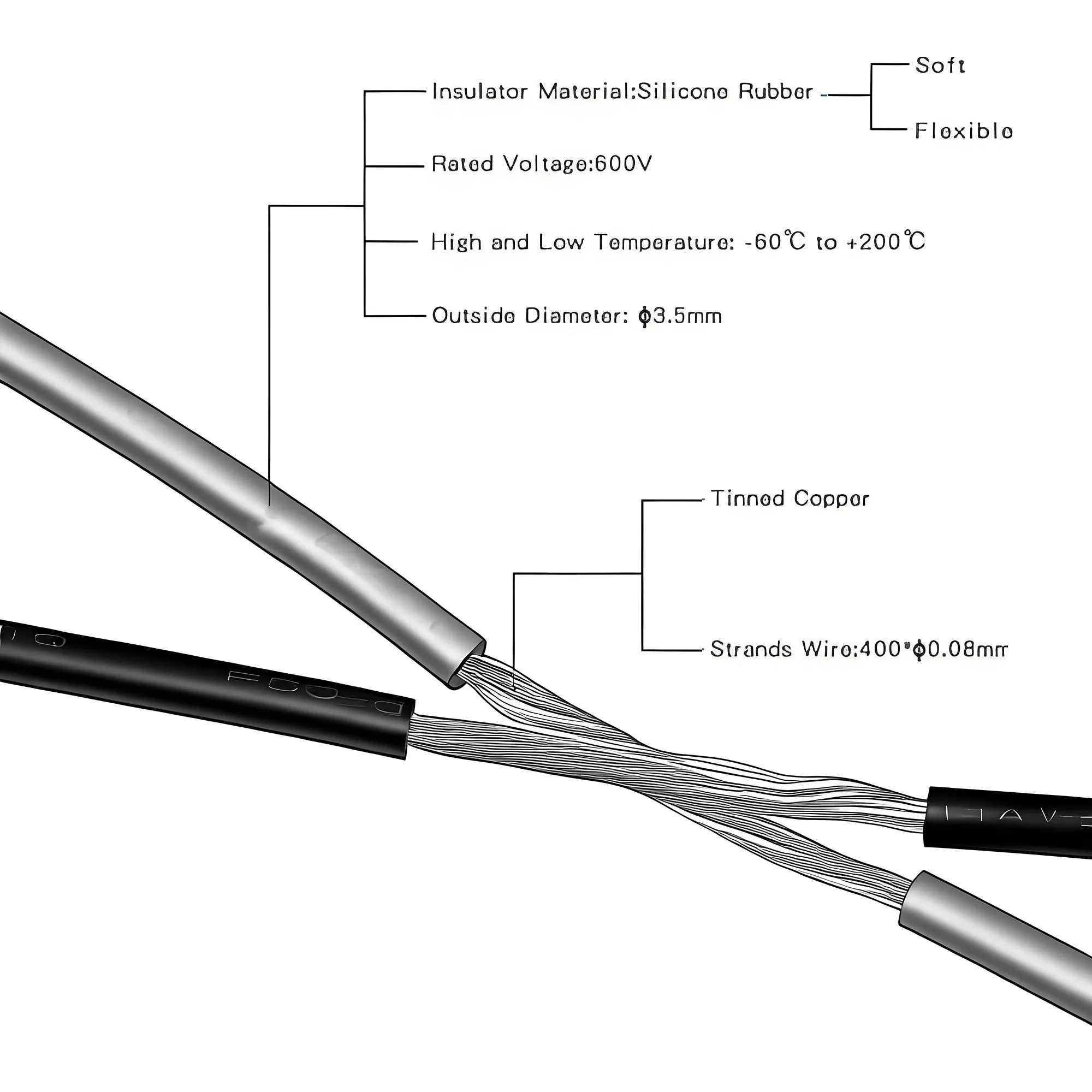

Hook‑up wire is typically made from stranded copper or aluminum conductors and is covered with an insulating layer made from materials such as PVC, Teflon, or silicone rubber. Its design allows for easy routing and soldering, making it ideal for:

Hook‑up wire comes in various types depending on the application and environmental conditions. Key factors include the gauge (or size), insulation material, and conductor type. Here are some common variations:

Solid vs. Stranded Wire:

Insulation Materials:

Conductor Materials:

Electronic Prototyping & DIY Projects:

Ideal for breadboarding and connecting components in lab settings or home workshops.

Internal Wiring in Appliances:

Used to connect switches, sensors, and circuit boards in household devices.

Automotive Wiring:

Found in wiring harnesses where flexible, durable connections are required.

Control Circuits & Signal Transmission:

Frequently used for low-power control signals in various electronic systems.

Q1: What gauge of hook‑up wire should I use for breadboarding?

Answer:

For breadboarding and low-power prototyping, 22‑ to 26‑AWG hookup wire is common. Thinner wires (26‑AWG) are more flexible but have higher resistance, while thicker wires (22‑AWG) can carry more current and are less prone to voltage drop.

Reference:

Q2: Can hook‑up wire be used in high-current applications?

Answer:

Hook‑up wire is generally intended for low-power signal and control applications. For higher currents, such as those in power distribution or motor connections, thicker wires with proper insulation (and sometimes special construction like stranding or heat resistance) are required.

Reference:

Q3: What is the typical insulation color code for hook‑up wire?

Answer:

Hook‑up wire is available in multiple colors. Although there is no universal code for hookup wire in prototyping, many electronics enthusiasts follow these conventions: red for power, black for ground, white or gray for signal, and other colors for additional functions. Always verify with your project requirements.

Reference:

Q4: What insulation material is best for high-temperature environments?

Answer:

For high-temperature applications, Teflon (PTFE) and silicone rubber are preferred due to their excellent thermal stability and chemical resistance compared to PVC.

Reference:

| Wire Type | Conductor Material | Insulation Material | Common Gauges (AWG) | Typical Applications |

|---|---|---|---|---|

| Standard Hook‑up Wire | Copper | PVC | 22 – 26 | Breadboarding, signal wiring, low-current tasks |

| High‑Temperature Hook‑up Wire | Copper | Teflon (PTFE) / Silicone | 20 – 24 | Automotive, aerospace, industrial circuits |

| Flexible Hook‑up Wire | Stranded Copper | Silicone Rubber | 24 – 28 | Wiring in dynamic environments, robotics |

Hook‑up wire is an essential component in a wide range of electronic and electrical applications—from simple breadboard projects to complex automotive wiring. Understanding the different types, materials, and specifications of hook‑up wire is key to selecting the right wire for your project. Whether you need a flexible, colorful wire for prototyping or a high‑temperature variant for harsh environments, always consider factors such as gauge, insulation material, and current requirements.

For further information, check out: