Time: 2025-04-15 03:34:25 Source: Henan Province Jianyun Cable Co., Ltd.

Low voltage wires are electrical conductors designed to operate at voltages below 50V AC (alternating current) or 120V DC (direct current), as defined by standards like the National Electrical Code (NEC). These wires are used in applications where high power isn’t required, but precision and safety are critical, such as in signaling, control systems, and data transmission.

The primary function of low voltage wires is to transmit electrical signals or power with minimal energy loss and interference. For example, in a security system, a low voltage wire might carry a 12V signal from a control panel to a motion sensor, activating an alarm when motion is detected. Because the voltage is low, the risk of electrical shock is significantly reduced, making these wires ideal for applications where safety is a priority, such as in homes or public spaces.

Low voltage wires work by providing a conductive path for electrons to flow, often in the form of digital or analog signals. They’re typically paired with devices like transformers or power supplies that step down higher voltages to safe levels. Think of low voltage wires as the delicate brushstrokes in a painting—while they don’t carry the bold colors of high-voltage power lines, they add the fine details that bring the picture to life.

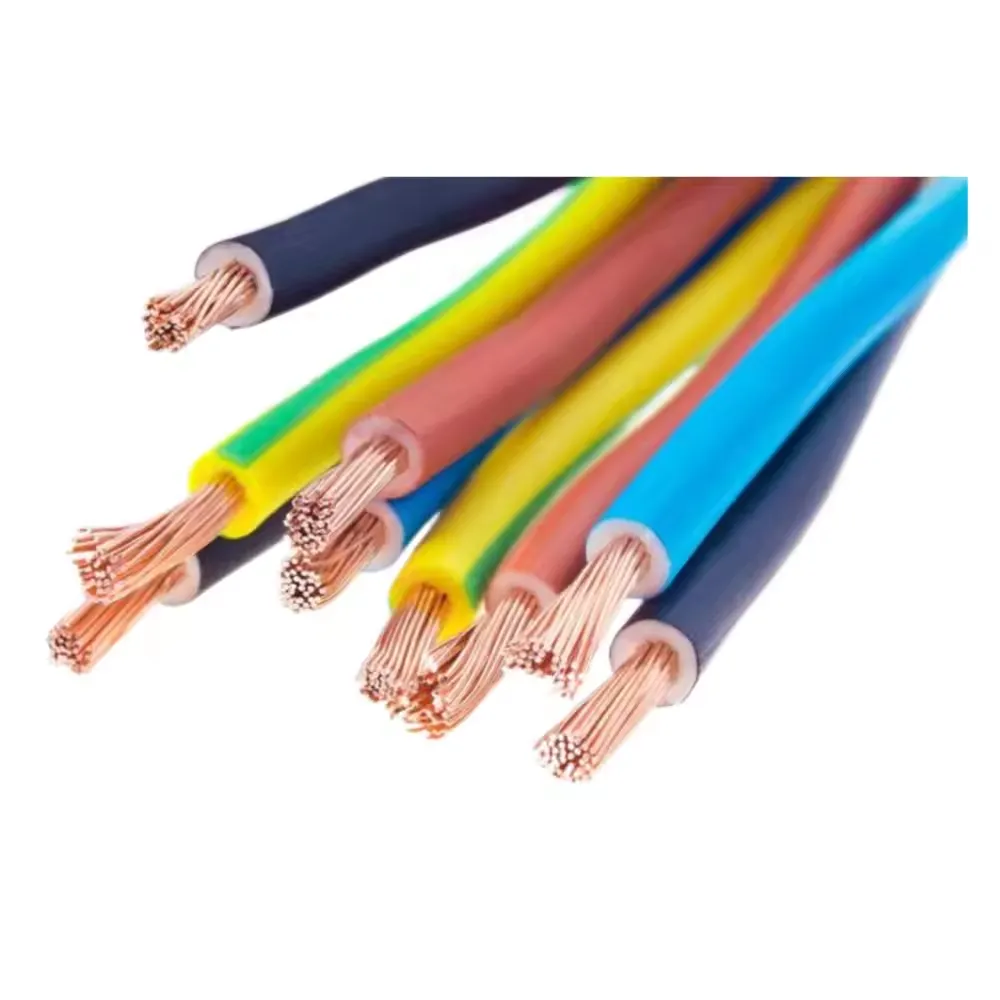

Low voltage wires are designed for flexibility, safety, and signal integrity, with a structure that varies depending on their application. While simpler than high-voltage cables, their design still includes several key components to ensure reliable performance.

The design of a low voltage wire is like a lightweight backpack—it’s built to carry just what’s needed, with enough protection to handle the journey. For example, a low voltage wire in a smart home system might have two 22 AWG conductors, insulated with PE, and wrapped in a flexible PVC jacket to run through walls without damage.

Telecommunications relies heavily on low voltage wires to transmit voice, data, and video signals across networks. These wires are the backbone of systems like telephone lines, internet connections, and cable television, ensuring reliable communication over long distances.

In a typical office, low voltage wires might run from a router to workstations, delivering internet speeds up to 1 Gbps via Cat6 cables. Their ability to handle high-frequency signals with minimal loss makes them essential for modern connectivity. It’s like having a dedicated courier service for data—low voltage wires ensure messages get delivered quickly and accurately.

Industrial automation depends on low voltage wires to connect sensors, actuators, and control systems, enabling precise monitoring and control of machinery. These wires are critical for maintaining efficiency and safety in factories, warehouses, and production lines.

For example, in an automated assembly line, low voltage wires might connect a PLC to a robotic arm, sending signals to pick and place items with precision. Their reliability ensures that even a small signal error doesn’t halt production. In automation, low voltage wires are like the strings of a puppet—small but essential for controlling every movement.

Smart homes and buildings rely on low voltage wires to power and connect the systems that make them “smart,” from lighting controls to security cameras. These wires enable automation, energy efficiency, and convenience while keeping installations safe and unobtrusive.

In a smart home, low voltage wires might run through walls to connect a central hub to various devices, creating a seamless network of automation. They’re like the threads in a tapestry, weaving together the elements of a smart, connected living space.

Renewable energy systems, such as solar and wind installations, use low voltage wires to connect components, monitor performance, and ensure efficient energy transfer. These wires are designed to handle outdoor conditions while maintaining safety and reliability.

For example, in a solar-powered home, low voltage wires might connect a rooftop panel array to a battery bank, ensuring excess energy is stored safely. Their role in renewable energy is like the roots of a plant—small but essential for channeling energy from the source to where it’s needed.

Proper installation and maintenance of low voltage wires are key to ensuring safety, performance, and longevity, especially since they’re often used in sensitive applications like data transmission and control systems.

Installation Tips:

Maintenance Tips:

Proper installation and maintenance are like caring for a delicate instrument—they ensure the system performs flawlessly over time. In applications like telecommunications or smart homes, where reliability is critical, these practices are non-negotiable.

The history of low voltage wires is closely tied to the rise of telecommunications and automation. In the late 19th century, early telegraph and telephone systems used simple low voltage wires with cloth insulation, often prone to interference. The 20th century brought advancements like PVC insulation and twisted pair designs, improving signal clarity and durability. The digital revolution of the late 20th century spurred the development of specialized low voltage wires, such as Ethernet cables, to support high-speed data transmission. Today, low voltage wires continue to evolve with eco-friendly materials and enhanced shielding, meeting the demands of smart technology and renewable energy systems.

Low voltage wires may carry small currents, but their impact on modern industries is immense. From enabling high-speed telecommunications to powering smart homes and renewable energy systems, these wires provide the precision and safety needed for today’s technology-driven world. Their versatile design, combined with their role in diverse applications, makes them a cornerstone of innovation across sectors. By understanding their design, uses, and maintenance needs, we can harness their full potential to build safer, smarter, and more efficient systems. So, the next time you make a call, adjust your thermostat, or harness solar power, remember the humble low voltage wire—quietly connecting the future.