Time: 2025-03-23 02:26:16 Source: Henan Province Jianyun Cable Co., Ltd.

Low voltage (LV) power cables are an essential component of modern electrical systems, facilitating the safe and efficient transmission of electricity for a wide range of applications. Defined as cables with a rated voltage not exceeding 0.6/1 kV (600 volts for DC or 1000 volts for AC), they are widely used in residential, commercial, and industrial settings. This article explores the key aspects of LV power cables, addressing common questions from multiple angles—design, applications, materials, and challenges—while providing clear answers backed by scientific principles and practical insights.

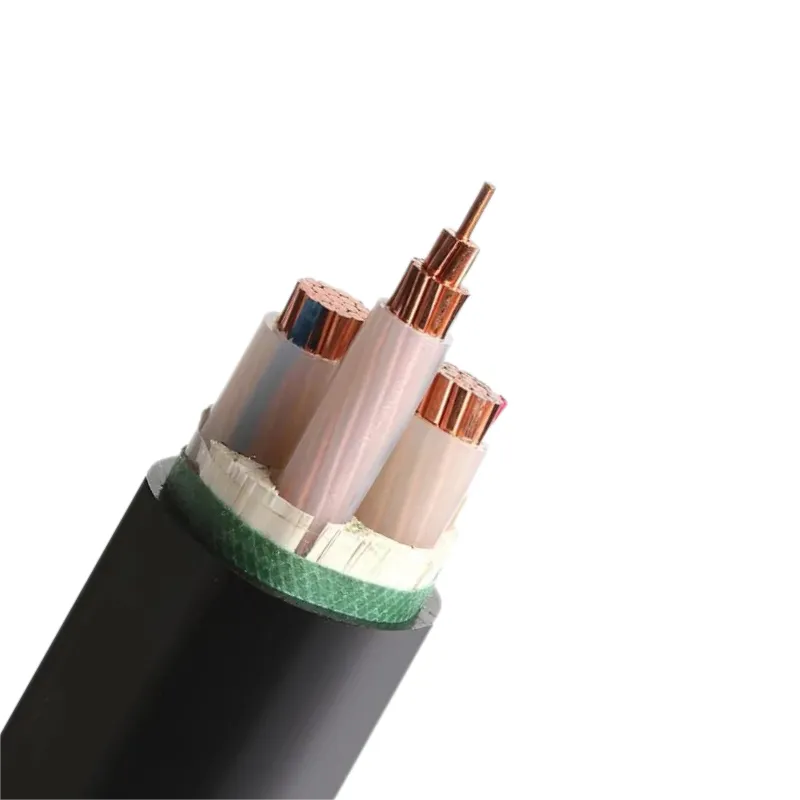

Low voltage power cables are electrical cables designed to transmit power or signals at voltages up to 0.6/1 kV. Unlike high voltage (HV) cables, which handle large-scale power distribution (typically above 1 kV), or medium voltage (MV) cables (3-35 kV), LV cables cater to localized power needs, such as household wiring, industrial machinery, and control systems. They consist of three primary components: a conductor (usually copper or aluminum), insulation (e.g., PVC or XLPE), and a protective sheath.

Below, we address several critical questions about LV power cables, offering a deeper understanding of their functionality and significance.

LV power cables are engineered with specific layers to ensure safety and performance:

Answer: The combination of these components ensures efficient current flow, insulation from external interference, and durability in various conditions.

LV cables are versatile and found in numerous settings:

Answer: Their reliability and adaptability make LV cables indispensable for both everyday and specialized electrical needs.

The choice of materials directly impacts a cable’s efficiency, longevity, and safety:

Answer: Material selection balances cost, performance, and environmental suitability, tailored to specific use cases.

Compared to traditional overhead power lines, LV cables offer distinct benefits:

Answer: These advantages make LV cables a preferred choice in modern infrastructure projects despite higher installation costs.

While effective, LV cables encounter several challenges:

Answer: Advances in materials (e.g., low-smoke halogen-free cables) and diagnostic techniques (e.g., partial discharge testing) help mitigate these issues.

To illustrate the diversity of LV power cables, the table below compares common types based on key parameters.

| Cable Type | Conductor | Insulation | Voltage Rating | Typical Use | Key Feature |

|---|---|---|---|---|---|

| PVC Insulated Cable | Copper | PVC | 0.6/1 kV | Household wiring | Cost-effective, flexible |

| XLPE Insulated Cable | Aluminum | XLPE | 0.6/1 kV | Industrial power supply | High heat resistance |

| Rubber Sheathed Cable | Copper | Rubber | 300/500 V | Portable equipment | Flexibility, durability |

| Control Cable | Copper | PVC | 450/750 V | Automation systems | Multi-core, signal-focused |

Table 1: Comparison of Low Voltage Power Cable Types

Research highlights the evolving nature of LV cable technology. For instance, studies on insulation degradation (e.g., water treeing) have led to the development of tree-resistant XLPE, enhancing cable lifespan. Additionally, smart cable technologies with embedded sensors allow real-time monitoring of performance, reducing downtime and maintenance costs. These advancements underscore the intersection of materials science and electrical engineering in improving LV systems.

Low voltage power cables are the unsung heroes of electrical infrastructure, delivering power safely and reliably across diverse applications. From their layered design to their material composition, these cables are engineered to meet specific demands while overcoming environmental and operational challenges. As technology advances, innovations in materials and monitoring promise even greater efficiency and sustainability for future LV cable systems.