Time: 2025-03-16 12:54:11 Source: Henan Province Jianyun Cable Co., Ltd.

Keywords: Medium Voltage Cable, Conductor Shielding, XLPE Cable, Conductor Stranding, Cable Reliability, Shielding Depression, Material Selection, Equipment Control

Medium voltage cross-linked polyethylene (XLPE) cables are critical for delivering power in cities and industries, but they’re not flawless. A study by Liu Yang and Jian Bingyu, published in Wire & Cable (December 2024), tackles a pesky problem: conductor shielding depression. This is when the shielding layer around the cable’s conductor gets uneven or sunken, risking electrical failures. The researchers dig into why this happens—looking at conductor design, shielding materials, production processes, and equipment—and suggest practical fixes. This article simplifies their findings, analyzes their impact, and explains why it matters for anyone interested in reliable power cables, all while boosting your knowledge and our site’s ranking!

Picture a medium voltage cable—say, 10 to 35 kV—running power to your neighborhood. Inside, it has a conductor (usually copper or aluminum) wrapped in a shielding layer to keep the electricity flowing smoothly and safely. If that shield sinks or gets bumpy (what the study calls “depression”), it can cause weak spots, leading to breakdowns or even fires. The researchers studied this issue in real-world XLPE cables, pinpointing causes and offering solutions. Their work is a must-read for cable makers and power companies aiming to keep the lights on without hiccups.

Shielding depression happens when the conductor’s outer shield isn’t smooth or tight against the conductor strands. It’s not just cosmetic—it can mess up the cable’s electrical performance. The study identifies four main culprits:

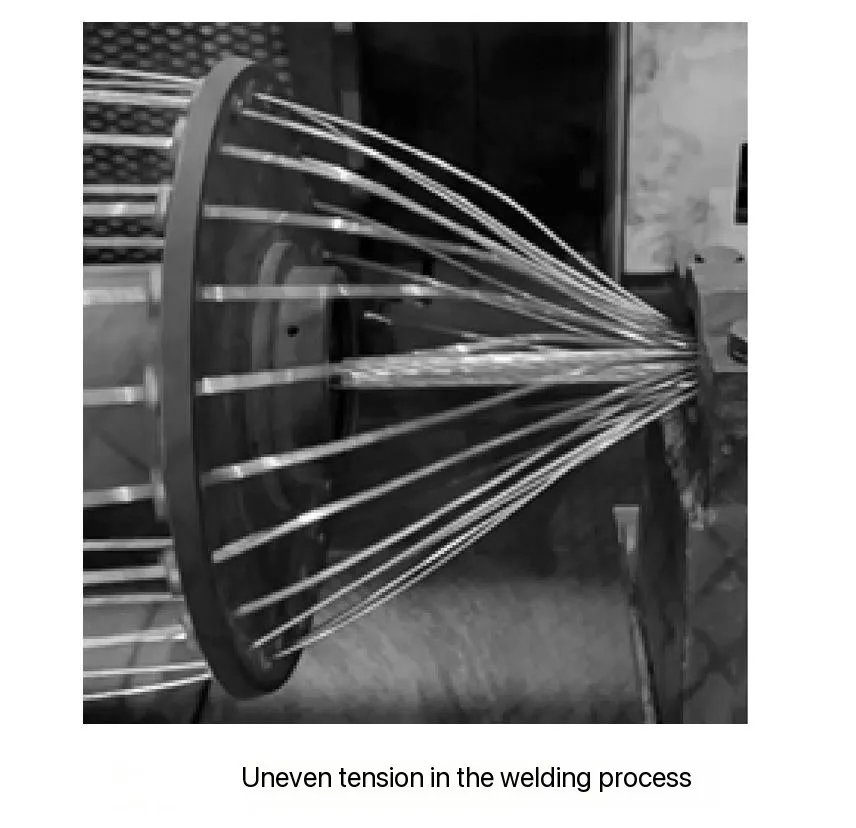

The conductor is made of many thin wires twisted into a solid core. The study explains that if these wires aren’t twisted tightly or evenly:

For example, if the outer layer’s strands aren’t uniform, the shield can’t sit flat, causing depressions.

The shield is extruded over the conductor in a process called triple co-extrusion (conductor shield, insulation, and insulation shield all at once). The study highlights:

Choosing a shield with a high melt index can reduce depressions by ensuring it hugs the conductor tightly.

Cross-linking makes XLPE cables tough by chemically bonding the polyethylene molecules. But if it’s not done right:

The study suggests checking annealing stability and extrusion settings to keep everything uniform.

The machines twisting, annealing, and extruding the cable need to be spot-on. For instance:

The researchers recommend regular checks and tweaks to keep equipment reliable.

The study offers practical fixes:

Table 1: Causes and Fixes for Shielding Depression

| Cause | Problem Description | Solution |

|---|---|---|

| Loose Stranding | Gaps between strands let shield sink | Tighten stranding process |

| Poor Annealing | Stiff strands spring back, uneven shield | Increase annealing checks (10–15%) |

| Bad Joints | Bumps from welds or presses | Improve joint techniques |

| Wrong Shield Material | Shield doesn’t fill conductor gaps | Use high melt index material |

| Uneven Extrusion | Shield doesn’t bond evenly | Adjust pressure and temperature |

The study ties shielding quality to the material’s melt index. A simplified version of their idea is:

Shield Fit=Melt IndexDensity\text{Shield Fit} = \frac{\text{Melt Index}}{\text{Density}}Shield Fit=DensityMelt Index

Higher “Shield Fit” means the material flows better into gaps, reducing depressions. (Note: This is a conceptual simplification, not a direct formula from the paper.)

Shielding depression isn’t just a manufacturing quirk—it’s a reliability risk. A bumpy shield can lead to partial discharges (tiny sparks) that degrade the cable over time. The study’s focus on medium voltage XLPE cables is spot-on, as these are widely used in urban grids where downtime is costly.

The annealing fix (boosting elongation by 10–15%) is a gem. It’s simple but tackles a root cause: uneven strand stiffness. Pairing this with high melt index shielding material doubles down on ensuring a snug fit, which could cut defects significantly.

The study’s light on data—like how much depression affects cable life or exact melt index numbers. More stats could strengthen their case. Also, they don’t explore cost: upgrading equipment or materials might pinch budgets, and that’s worth weighing.

This could set a new benchmark for medium voltage cable production. If manufacturers adopt these fixes, we might see fewer cable failures, saving millions in repairs and outages. It’s a win for reliability and safety—key buzzwords in the power sector.

Table 2: Potential Benefits

| Improvement | Benefit | Industry Impact |

|---|---|---|

| Better Stranding | Fewer gaps, smoother shield | Higher production quality |

| High Melt Index | Tighter shield fit | Reduced electrical faults |

| Stable Annealing | Uniform conductor softness | Longer cable lifespan |

| Equipment Checks | Consistent output | Lower defect rates |

If you’re in the cable game, this study hands you a playbook to make better products. For the rest of us, it’s about trust—knowing the cables powering our homes and offices won’t fail because someone figured out how to fix a sneaky flaw. Better cables mean fewer blackouts, and that’s something we can all cheer for.

Liu Yang and Jian Bingyu’s research pulls back the curtain on conductor shielding depression in medium voltage XLPE cables, showing it’s a fixable problem rooted in stranding, materials, processes, and equipment. Their solutions—tighter stranding, smarter material picks, and machine precision—offer a clear path to more reliable cables. It’s not just technical jargon; it’s a practical guide that could keep power flowing smoothly in cities worldwide. Next time your lights stay on during a storm, you might just thank a well-shielded cable—and this study.