Time: 2025-04-14 12:36:34 Source: Henan Province Jianyun Cable Co., Ltd.

Cross-linked polyethylene (XLPE) is widely used in power cables but has limitations including non-recyclability, high energy consumption, and harmful byproducts. In contrast, polypropylene (PP) is a thermoplastic, recyclable material with excellent thermal and mechanical properties. This study presents the design and performance of PP-insulated power cables for 8.7/15 kV and 26/35 kV systems, with enhanced long-term operating temperature of 105°C.

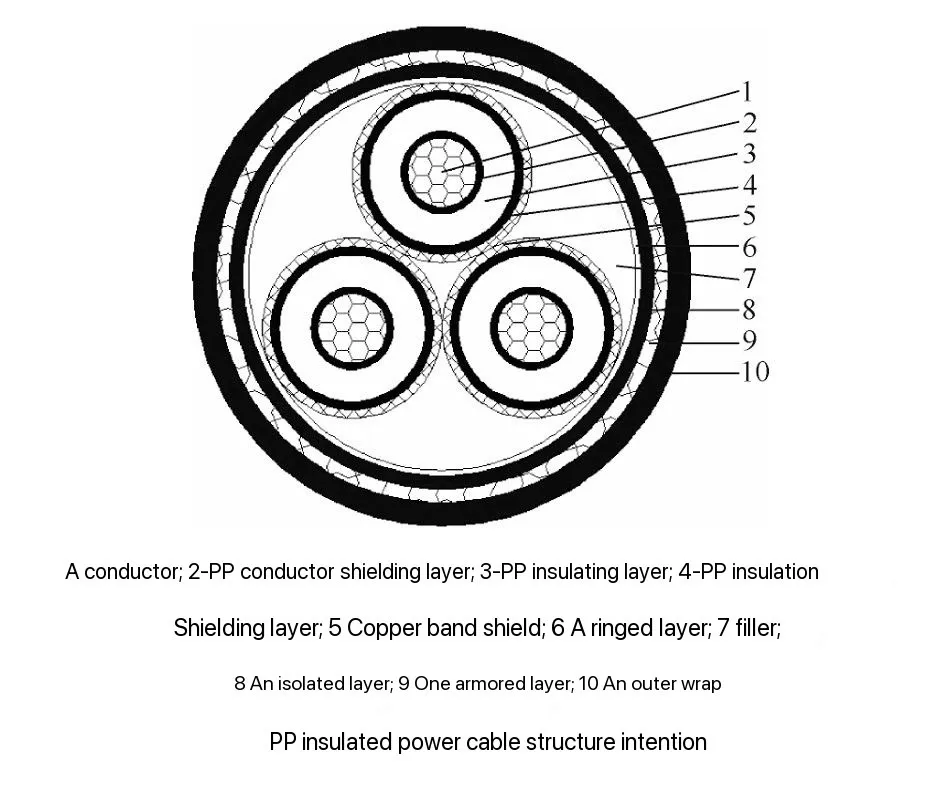

The cable uses a tri-layer co-extrusion process with PP-based shielding and insulation. Key structural features include PP conductor shielding, insulation layer, insulation shielding, copper tape, fillers, armor, and outer sheath. Temperature control during extrusion ensures low internal stress and improved dielectric performance.

Modified PP resin blended with POE elastomer and stabilizers. Dielectric strength: >35 kV/mm; actual: 39–41 kV/mm.

For 26/35 kV systems: theoretical value = 1.38 mm, corrected with temperature, aging, and safety factors = 4.79 mm. For 8.7/15 kV systems: nominal insulation thickness = 3.7 mm. For impulse voltage, final nominal thickness = 7.6 mm.

Example calculation for 3×300 mm² cable at 26/35 kV yields η = 0.76, confirming efficient electric field distribution.

For 26/35 kV cables, m = 1.39. Range of 1.2–1.6 ensures sufficient overvoltage protection.

Ampacity (carrying current) of PP-insulated cable is calculated using standard formulas, considering 105°C operation.

For 3×300 mm² cables:

| Voltage Level (kV) | Installation | PP Cable (A) | XLPE Cable (A) | Improvement (%) |

|---|---|---|---|---|

| 26/35 | Buried | 545 | 500 | 9.00 |

| 26/35 | In Air | 591 | 521 | 13.44 |

| 8.7/15 | Buried | 545 | 500 | 9.00 |

| 8.7/15 | In Air | 582 | 512 | 13.67 |

Tests include aging, shrinkage, water absorption, thermal shock, and low-temperature tensile. Results meet GB/T 12706.3—2020 standards.

| Test Item | Requirement | Group 1 | Group 2 | Group 3 |

|---|---|---|---|---|

| Tensile Strength (Before Aging) | ≥12.5 | 33 | 34 | 31 |

| Elongation at Break (%) | ≥450 | 540 | 510 | 530 |

| Shrinkage (%) | ≤4 | 1 | 1 | 1 |

| Water Absorption (mg/cm²) | ≤1 | 0.08 | 0.08 | 0.09 |

| Test | Condition | Result |

|---|---|---|

| tanδ Measurement | 110–115°C, 2 kV | 2.9×10⁻⁴ (≤1.0×10⁻³) |

| Impulse Voltage | 200 kV, ±10 times | No breakdown |

| AC Withstand | 65 kV, 15 min | No breakdown |

| Power Frequency Withstand | 4U₀, 4 h | No breakdown |

| Item | Standard | Result |

|---|---|---|

| Acid Gas Content (%) | ≤0.5 | <0.5 |

| pH | ≥4.3 | 5.4 |

| Conductivity (μS/mm) | ≤10 | 0.26 |

| Smoke Density (% light transmittance) | ≥60 | 78 |

| Vertical Flame Propagation | ≤2.5 m | 0.25 m |

A 3×400 mm² PP cable has been in service in Qingdao Industrial Zone since 2023, with no operational issues. Routine inspections and testing confirm compliance with GB 50150-2016 standards.

The development of 105°C medium voltage PP-insulated cables offers an eco-friendly, recyclable alternative to XLPE, with improved current-carrying capacity and thermal performance. The cables perform reliably in both laboratory and field environments, with significant benefits in electrical safety margin and environmental impact. Future work will focus on long-term reliability under multiple stress conditions.