Time: 2025-03-09 10:15:21 Source: Henan Province Jianyun Cable Co., Ltd.

Polypropylene (PP) insulated power cables have gained significant attention due to their excellent electrical properties, environmental friendliness, and recyclability. As China promotes sustainable energy solutions and carbon neutrality, PP cables are emerging as a key component in the power industry. This article provides an overview of PP insulated power cables, their advantages, current standardization progress, and future development directions.

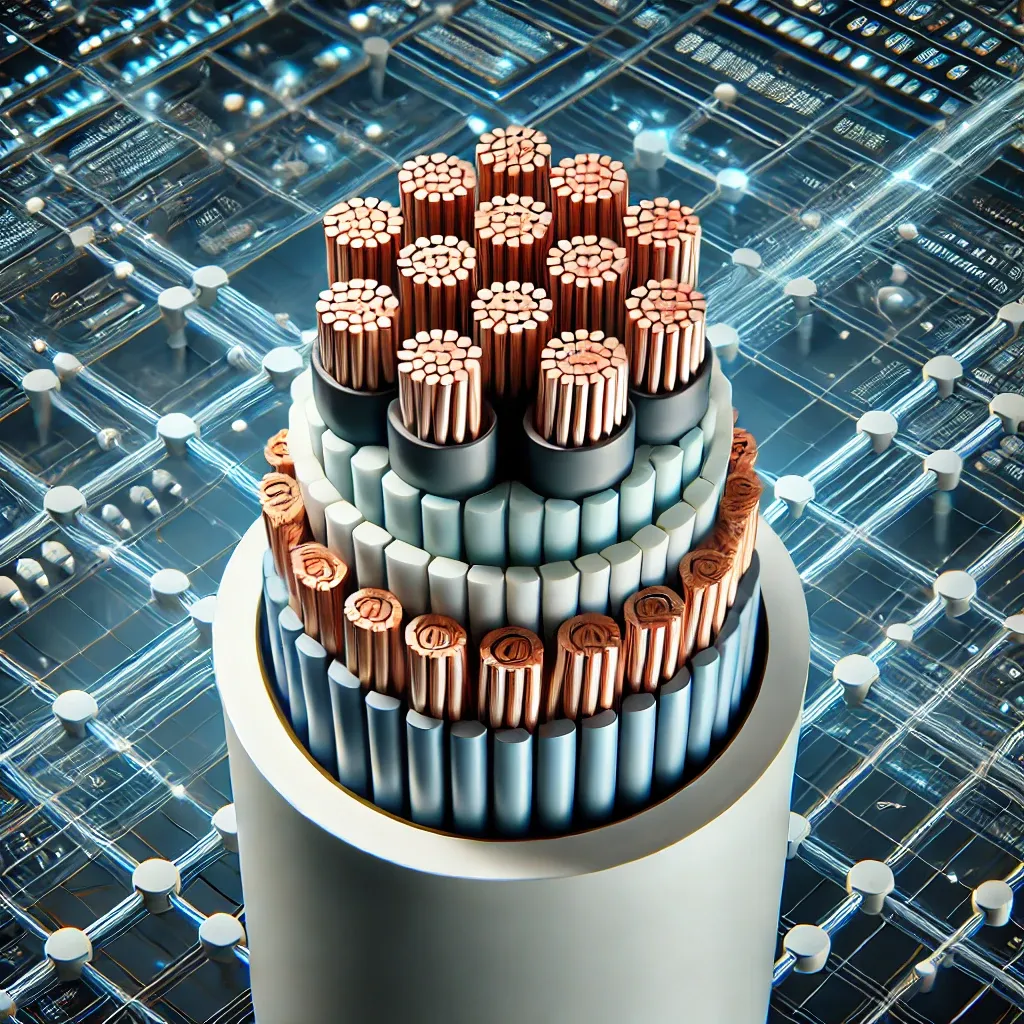

Power cables are critical for stable electricity transmission. Traditionally, cross-linked polyethylene (XLPE) has been the dominant insulation material due to its high electrical and thermal performance. However, XLPE cables cannot be recycled, leading to environmental concerns. Polypropylene, as a thermoplastic material, offers a sustainable alternative with the following benefits:

The development of PP insulated power cables in China has been progressing steadily, following international trends. Countries like Italy, South Korea, Japan, and Switzerland have already implemented PP cable technologies in medium- and high-voltage applications.

China’s research on PP power cables began in 2014, led by institutions such as Tsinghua University, Shanghai Jiao Tong University, Tianjin University, and Harbin Institute of Technology. These efforts have been complemented by major power grid research centers and industrial companies like China Petroleum & Chemical Corporation (Sinopec) and China National Nuclear Corporation (CNNC).

To ensure the safe and efficient application of PP cables, China has developed industry standards. Key standardization efforts include:

PP materials require modifications to enhance their mechanical properties while maintaining electrical performance. Current research focuses on:

Chinese industry standards specify test requirements for dielectric loss (tan δ), volume resistivity, tensile strength, elongation at break, and thermal aging resistance. Additionally, safety considerations such as flame retardancy, low smoke emission, and recyclability are being incorporated into future cable designs.

The future of PP insulated power cables in China is promising. Key development trends include:

Polypropylene insulated power cables represent the future of eco-friendly and high-performance electrical transmission in China. With strong industry support, ongoing research, and advancing standards, PP cables are poised to replace traditional insulation materials, providing a more sustainable, efficient, and cost-effective solution for modern power networks.

By staying at the forefront of these developments, manufacturers and power grid operators can ensure they meet the increasing demands for sustainability, efficiency, and reliability in China’s evolving energy landscape.