Power Cables: The Unsung Heroes of Our Electrified World

Time: 2025-04-14 09:17:35

Source: Henan Province Jianyun Cable Co., Ltd.

Table of Contents

What Is the Structure of a Power Cable?

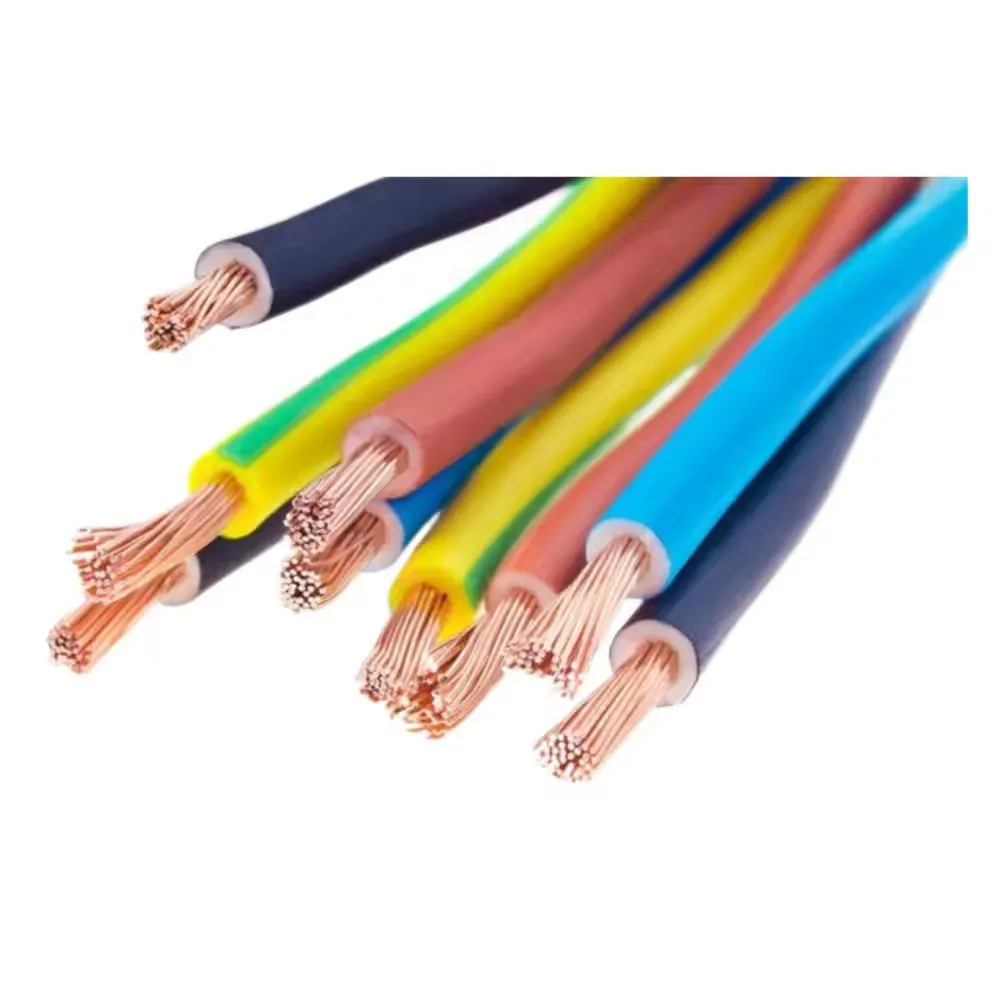

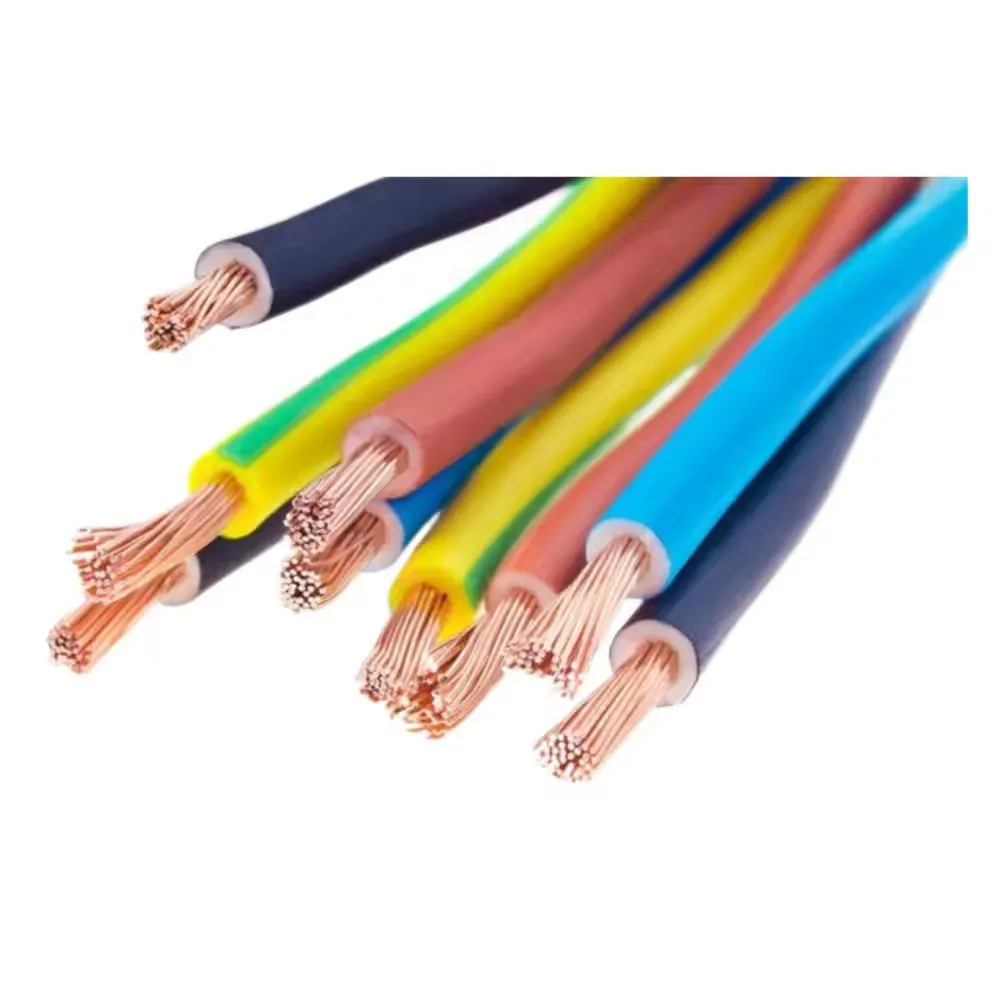

At its core, a power cable is a carefully engineered assembly designed to transmit electricity safely and efficiently. Most power cables consist of three primary components: the conductor, the insulation, and the outer sheath. Some advanced cables also include a shielding layer for added functionality.

-

Conductor: This is the heart of the cable, typically made of copper or aluminum, chosen for their excellent conductivity. Copper is pricier but conducts electricity better, while aluminum is lighter and more cost-effective for large-scale applications like overhead power lines.

-

Insulation: Surrounding the conductor, the insulation layer prevents unwanted electrical contact and leakage. Materials like polyvinyl chloride (PVC) or cross-linked polyethylene (XLPE) are common, selected for their ability to withstand heat and resist breakdown over time.

-

Shielding Layer: Found in high-performance cables, shielding reduces electromagnetic interference (EMI), ensuring stable performance in sensitive environments like hospitals or data centers.

-

Outer Sheath: The cable’s protective skin, usually made of durable PVC or rubber, guards against physical damage, moisture, and extreme temperatures.

Think of a power cable as a multi-layered burrito: each layer serves a purpose, working together to deliver electricity safely. For example, a household extension cord might seem simple, but its layers ensure you can plug in your coffee maker without sparking a fire.

How Is a Power Cable’s Current-Carrying Capacity Determined?

The ability of a power cable to carry current—its ampacity—is a critical factor in its design and application. This capacity depends on several variables: the conductor’s cross-sectional area, the material, and the environmental conditions.

-

Cross-Sectional Area: Measured in square millimeters (mm²) or American Wire Gauge (AWG), a larger area allows more current to flow. For instance, a 2.5 mm² copper cable can safely handle about 25 amps, enough for a 5500W appliance at 220V.

-

Material: Copper conducts better than aluminum, meaning a copper cable can carry more current for the same size. However, aluminum’s lower cost makes it popular for long-distance transmission lines.

-

Environment: Temperature, ventilation, and bundling affect ampacity. A cable in a hot, enclosed space loses capacity because heat buildup increases resistance. Standards like the National Electrical Code (NEC) provide guidelines to account for these factors.

Choosing the right cable is like picking a straw for a smoothie: too thin, and it clogs (or overheats); too thick, and it’s overkill. Overloading a cable can lead to melting insulation or fires, so matching the cable to the load is crucial.

Why Do Some Power Cables Have a Ground Wire?

If you’ve ever noticed a third prong on a plug, you’ve encountered a ground wire—the unsung hero of electrical safety. The ground wire provides a low-resistance path for stray current to flow into the earth, preventing electric shocks and equipment damage.

In a typical three-pin plug, you’ll find:

-

Live (Hot) Wire: Carries current to the device.

-

Neutral Wire: Completes the circuit, returning current to the source.

-

Ground Wire: Remains inactive unless there’s a fault, like a short circuit or insulation failure.

Imagine your appliance’s metal casing becomes electrified due to a loose wire. Without a ground wire, touching it could send a lethal current through you. With grounding, the current diverts safely to the ground, tripping a circuit breaker or fuse to cut power. Devices like washing machines, refrigerators, and computers often include ground wires because their high power or metal casings pose greater risks. It’s like having a fire extinguisher—you hope you never need it, but it’s a lifesaver when you do.

What Do Safety Certification Marks on Power Cables Mean?

Look closely at a power cable, and you’ll likely spot symbols like UL, CE, or CCC. These are safety certification marks, proof that the cable has passed rigorous tests for performance and reliability. They’re the electrical equivalent of a Michelin star for a restaurant—assurance of quality you can trust.

-

UL (Underwriters Laboratories): A U.S.-based standard, UL certification ensures cables meet fire resistance, insulation strength, and durability requirements.

-

CE (Conformité Européenne): Common in Europe, CE marks indicate compliance with EU safety and environmental standards.

-

CCC (China Compulsory Certification): Mandatory in China, CCC tests cables for electrical safety and thermal stability, especially under high loads.

These certifications involve brutal testing: cables are subjected to high voltages, extreme temperatures, and physical stress to ensure they won’t fail in real-world conditions. For consumers, a certified cable means peace of mind—whether you’re charging a phone or powering a factory, it’s built to perform safely. Always check for these marks when buying cables; an uncertified one is like a mystery meat sandwich—cheap, but risky.

How Do You Choose the Right Power Cable for Your Needs?

Selecting a power cable isn’t just grabbing the first one off the shelf—it’s about matching the cable to the task. Key factors include power requirements, environmental conditions, length, and flexibility.

-

Power Requirements: Calculate the device’s wattage and voltage to determine the current (Watts = Volts × Amps). A vacuum cleaner pulling 1200W at 120V needs a cable rated for at least 10A. Undersizing risks overheating; oversizing wastes money.

-

Environment: Indoor cables can use basic PVC insulation, but outdoor ones need UV-resistant, waterproof sheaths. In harsh settings like construction sites, opt for ruggedized cables with extra-thick jackets.

-

Length: Longer cables increase resistance, causing voltage drops. For a 50-meter run, you might need a thicker cable to maintain performance. Think of it like watering a garden—too long a hose, and the pressure weakens.

-

Flexibility: Frequent bending (e.g., for stage lighting) demands cables with stranded conductors and soft insulation to prevent cracking.

A practical tip: for home use, a 16 AWG extension cord suits low-power devices like lamps, while heavy appliances like air conditioners need 12 AWG or thicker. Choosing wisely ensures efficiency and safety, like fitting the right tires to a car for the road ahead.

What Are the Differences Between AC and DC Power Cables?

Power cables come in two flavors: those for alternating current (AC) and direct current (DC). Understanding their differences is key to using them correctly.

-

AC Power Cables: Used in homes and offices, AC cables handle the oscillating current from power grids (e.g., 120V/60Hz in the U.S., 220V/50Hz in Europe). They’re designed for higher voltages and longer distances, with insulation to prevent leakage during current reversals. Your laptop’s power cord is an AC cable, feeding into an adapter that converts to DC internally.

-

DC Power Cables: Common in electronics, solar panels, and batteries, DC cables carry steady, unidirectional current at lower voltages (e.g., 5V for USB chargers, 12V for car systems). They require less insulation since DC doesn’t induce as much interference, but they’re sensitive to length due to voltage drops.

For example, a USB-C cable charging your phone is a DC cable, optimized for compact size and low power. Meanwhile, the cable connecting your fridge to the wall is AC, built for higher loads. Mixing them up—like plugging a DC device into an AC