Time: 2025-03-19 12:58:03 Source: Henan Province Jianyun Cable Co., Ltd.

High-voltage and ultra-high-voltage underground power cables require metal sheaths to provide mechanical protection, waterproofing, and electrical shielding. A smooth aluminum sheath offers advantages over traditional corrugated aluminum sheaths, including better electrical contact and lower risk of insulation failure. However, if the aluminum sheath thickness is not optimized, it may wrinkle during bending, compromising cable performance.

This study introduces a short-circuit capacity-based design method for determining the optimal aluminum sheath thickness, ensuring both mechanical durability and electrical safety.

When designing aluminum sheath thickness, using values from corrugated aluminum sheaths can lead to wrinkling after bending, especially in 220 kV large-section high-voltage cables.

From material thickness and curvature characteristics:

where:

Thicker sheaths have lower curvature but reduced flexibility, requiring an optimized balance.

To determine the optimal sheath thickness, the study applies the short-circuit current formula from IEC 60949:1988:

where:

For 220 kV, 2500 mm² cables, the initial sheath temperature (θi\theta_iθi) is 66.2°C, and the final temperature is 180°C, resulting in an optimal sheath cross-section of 780 mm², equivalent to a thickness of 2.0 mm.

Considering bending deformation during production, the final design thickness is set at 2.3 mm.

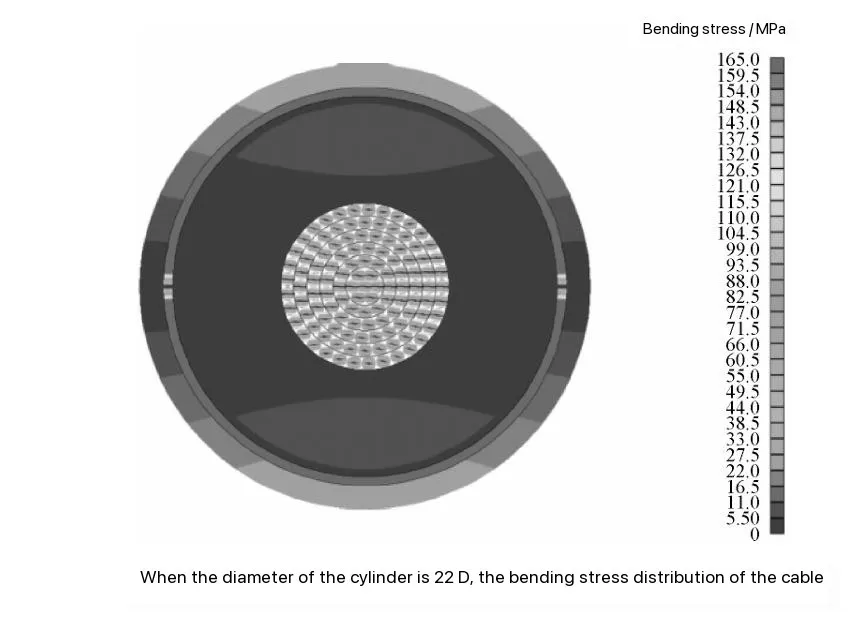

Using CableCAD simulation, stress distribution analysis confirms that the maximum stress concentrates in the aluminum sheath. When the cable bending radius is 22D (D = cable outer diameter), the sheath stress remains within the safety limit, preventing permanent deformation.

The sheath elongation rate is calculated as:

where:

When the bending radius is 11D, the outer sheath elongation is 4.3%, ensuring no irreversible deformation.

| Parameter | Standard Requirement | Measured Value |

|---|---|---|

| Tensile Strength (MPa) | 60-100 | 68-71 |

| Elongation at Break (%) | >16 | 19-22 |

The post-processing sheath thickness reduction improves tensile strength by 3.6%, while elongation remains above 16%, meeting standard requirements.

Following IEC TR 61901:2016 standards, external impact tests were conducted using a 27 kg free-fall hammer at a height of 0.27 m, striking the aluminum sheath four times.

The short-circuit capacity-based design method optimizes aluminum sheath thickness while maintaining mechanical and electrical reliability.

A thickness of 2.3 mm ensures no wrinkling, sufficient short-circuit capacity, and improved bending performance.

Impact tests confirmed that the optimized aluminum sheath provides adequate mechanical protection for high-voltage cable applications.