Time: 2025-04-18 15:56:27 Source: Henan Province Jianyun Cable Co., Ltd.

In cable nomenclature, "SY" typically refers to a steel wire braided control cable, though the exact origin of the term is not strictly standardized and may vary by manufacturer. The "S" often indicates steel wire braiding, and "Y" denotes PVC (polyvinyl chloride) insulation or sheathing, aligning with European naming conventions like those under VDE standards. SY cables are designed for low-voltage control applications, transmitting signals to manage machinery or equipment rather than delivering high-current power.

Rated typically for 300/500V or 450/750V, SY cables handle currents of a few amps per core, prioritizing flexibility and mechanical protection. Their steel braid distinguishes them from other control cables, offering durability in dynamic or moderately harsh environments. An SY cable is like a courier in a medieval town, weaving through busy streets (circuits) with a chainmail vest (steel braid) to safely deliver messages (signals) despite rough conditions.

SY cables are engineered for flexibility, signal integrity, and moderate mechanical protection, making them ideal for environments with movement or physical stress. Their construction includes several key layers, as detailed in the table below:

| Component | Description | Purpose |

|---|---|---|

| Conductor | Class 5 fine-stranded copper (IEC 60228) | Ensures high flexibility for dynamic use |

| Insulation | PVC (Polyvinyl Chloride) | Prevents short circuits, isolates signals |

| Armour | Galvanized steel wire braid | Protects against abrasion, crushing, EMI |

| Outer Sheath | PVC, often transparent or grey | Resists moisture, chemicals, UV exposure |

| Core Count | 2 to 50+ cores, numbered or color-coded | Supports multiple control signals |

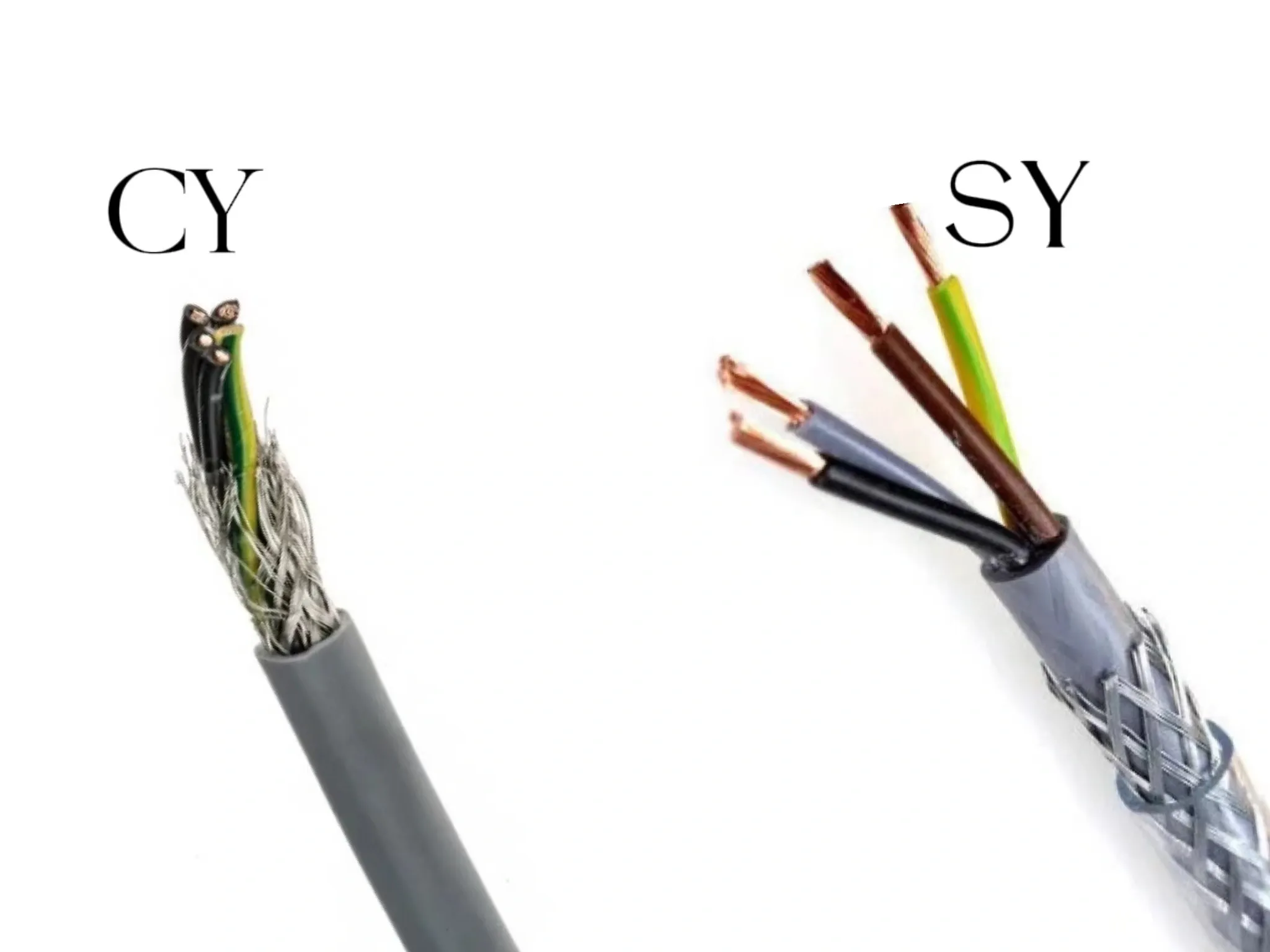

The Class 5 copper conductors, made of fine strands, allow the cable to bend repeatedly without breaking, rated for a bending radius of about 10x the cable diameter (e.g., 100mm for a 10mm cable). PVC insulation ensures electrical isolation, while the galvanized steel wire braid—covering 60–80% of the cable—shields against mechanical damage and provides limited electromagnetic interference (EMI) protection, though not as effective as foil-shielded cables like CY cables. The PVC sheath, typically 1–2mm thick, adds environmental resistance. Compared to unarmoured cables (e.g., YY) or heavily armoured ones (e.g., SWA), SY cables strike a balance, like a flexible spine with a protective exoskeleton, bending to fit tight spaces while resisting wear.

SY cables are employed in applications requiring flexible control wiring with moderate mechanical protection, particularly in industrial, commercial, and temporary setups. Key uses include:

SY cables are suited for indoor or sheltered environments, with operating temperatures typically from -5°C to +70°C. They’re not designed for direct burial or high-power applications, where SWA or STA cables are preferred, nor for high EMI environments, where CY cables with tinned copper braids excel. SY cables are like nimble couriers in an electrical network, delivering precise signals while dodging hazards with their steel braid armour.

Selecting and installing SY cables requires careful attention to ensure performance, safety, and compliance with standards like BS EN 50525-2-11 or VDE 0250. Here are practical considerations:

Proper installation involves securing cables with clips or trays, avoiding sharp bends, and using glands for terminations to maintain the braid’s integrity. Consulting a professional electrician ensures compliance with local codes, like NF C 15-100 in France. Choosing an SY cable is like picking the right gear for a hike—versatile for most trails but not suited for extreme cliffs or deep rivers.

The "SY" in cables denotes a flexible control cable with a steel wire braid, designed for transmitting low-voltage signals (300/500V) in industrial and commercial applications. Built with fine-stranded copper, PVC insulation, and a protective steel braid, SY cables offer flexibility and moderate mechanical protection. They’re used in automation, building controls, and machine tools, but not for high-power or heavily shielded applications. By considering voltage, mechanical stress, and environmental factors, you can select SY cables for reliable, safe control wiring in dynamic settings.