Time: 2025-03-29 11:39:58 Source: Henan Province Jianyun Cable Co., Ltd.

In the nuclear industry, the long-term reliability and safety of cable insulation materials are essential. One of the critical indicators of insulation performance is thermal aging behavior, often evaluated through activation energy. This article summarizes and analyzes a technical research paper that compares two widely used analytical methods—Thermogravimetric Analysis (TG) and Compensation Effect Analysis (CA)—in determining the activation energy of cross-linked polyethylene materials used in nuclear power cables. The article also comments on the scientific significance of this study and its practical value in industrial applications.

Nuclear power cables play a vital role in ensuring the stable operation of nuclear facilities. The insulation layer of these cables is commonly made from cross-linked polyethylene (XLPE), known for its high thermal stability and electrical insulation properties. However, long-term exposure to high temperatures, radiation, and mechanical stress leads to material aging and degradation.

To predict the lifespan and thermal stability of XLPE materials, researchers analyze the activation energy (Ea) associated with their thermal oxidative degradation. The higher the activation energy, the better the material’s resistance to thermal aging.

This paper focuses on comparing two prevalent methods for determining activation energy:

| Method | Full Name | Main Principle |

|---|---|---|

| TG Method | Thermogravimetric Analysis | Measures weight loss as a function of temperature. |

| CA Method | Compensation Effect Analysis | Uses a series of kinetic parameters to calculate Ea indirectly. |

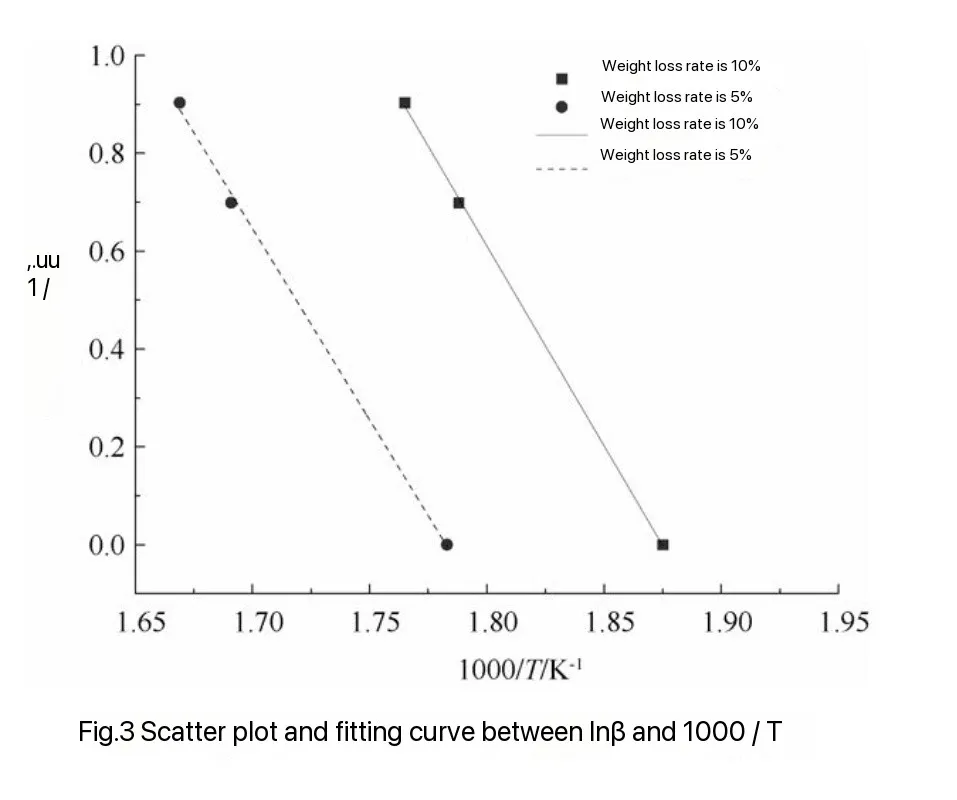

The TG method involves heating the sample under a controlled atmosphere and recording the weight loss as the temperature increases. The degradation process is analyzed based on the relationship between weight loss rate and temperature, from which activation energy is calculated using kinetic models such as the Ozawa-Flynn-Wall (OFW) and Kissinger-Akahira-Sunose (KAS) methods.

Advantages of TG Method:

Direct measurement

High accuracy

Standardized process

Limitations:

Requires complex data processing

Sensitive to test conditions

The CA method is a statistical approach that utilizes a compensation effect between activation energy and pre-exponential factors observed in different kinetic models. It is based on the observation that there is a linear relationship between ln(A) and Ea across various degradation reactions.

Advantages of CA Method:

Simplifies complex kinetic analysis

Efficient for large datasets

Limitations:

Relies on empirical fitting

Less accurate for materials with multi-stage degradation

The research used cross-linked polyethylene materials specific to nuclear cable applications and performed comparative analysis under identical test conditions.

| Parameter | TG Method Result | CA Method Result |

|---|---|---|

| Activation Energy (Ea) | ~180-210 kJ/mol | ~170-200 kJ/mol |

| Pre-exponential Factor A | Directly measured | Derived via compensation effect |

| Consistency | High at initial degradation stage | Slight deviation at later stages |

The key finding is that both methods produce comparable activation energy values in the early stages of thermal degradation. However, as degradation progresses, the CA method tends to underestimate activation energy due to simplified assumptions.

The study highlights the importance of methodological rigor when evaluating material properties for safety-critical applications. The consistency between the TG and CA methods reinforces the reliability of these analytical techniques, particularly for early-stage degradation analysis.

However, the study also reveals the limitations of the CA method in multi-stage degradation scenarios, underscoring the need for careful interpretation of results when using empirical statistical models.

For nuclear cable manufacturers and safety inspectors, this research offers clear guidance:

For preliminary assessments and large-scale material screening, the CA method is time-efficient and cost-effective.

For critical safety evaluations and long-term reliability analysis, the TG method is preferred due to its higher accuracy and scientific basis.

The paper acknowledges certain limitations:

The sample size was limited to specific nuclear-grade XLPE materials.

Environmental factors such as radiation and humidity were not included.

Future research may expand the scope to include:

Real-world aging conditions.

Multi-material comparison.

Integration of machine learning for kinetic modeling.

This comparative study provides valuable insights into two analytical approaches for evaluating the thermal oxidative stability of nuclear cable insulation materials. The findings suggest that while the TG method remains the gold standard for precise activation energy measurement, the CA method can serve as a complementary tool, particularly in early-stage analysis or large-scale material evaluation.

For professionals in the nuclear industry, understanding the pros and cons of these methods will enable better material selection, process optimization, and long-term safety assurance.

Thermogravimetric Analysis, Compensation Effect Analysis, Activation Energy, Cross-linked Polyethylene, Nuclear Cable, Thermal Aging, Material Degradation, Non-destructive Testing

[Source Paper: Comparative Analysis of Activation Energy of Cross-linked Materials for Nuclear Cables Based on TG Method and CA Method] (Your PDF file)

Flynn, J.H., & Wall, L.A. (1966). A quick, direct method for the determination of activation energy from thermogravimetric data. Journal of Research of the National Bureau of Standards.

Kissinger, H.E. (1957). Reaction kinetics in differential thermal analysis. Analytical Chemistry.