Time: 2025-03-12 14:41:18 Source: Henan Province Jianyun Cable Co., Ltd.

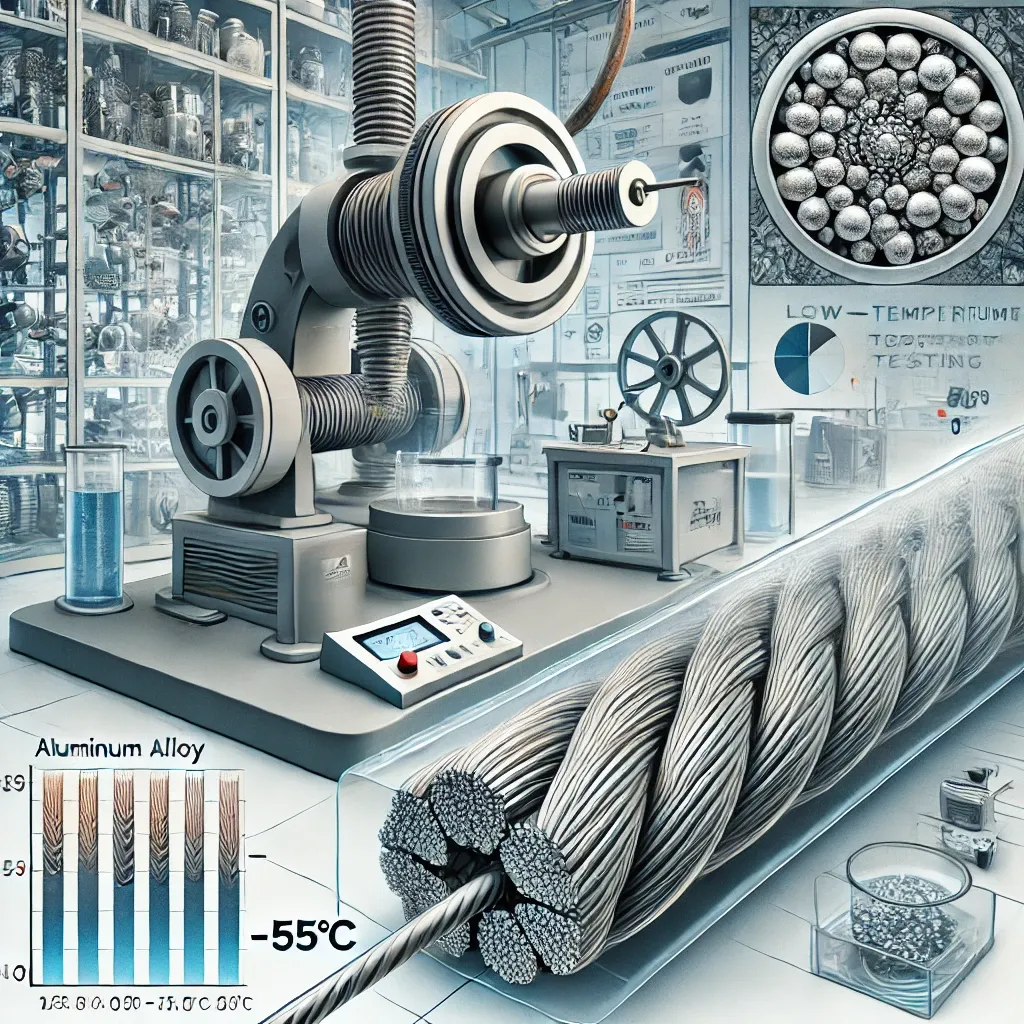

As the new energy sector continues to grow, wind power generation requires high-performance flexible cables that can withstand harsh environmental conditions, including extreme cold and repeated torsion (twisting) cycles. Traditionally, copper conductors have been used in these cables due to their excellent conductivity and mechanical properties. However, aluminum alloy conductors have emerged as a promising alternative due to their lower cost, lightweight nature, and recent improvements in mechanical strength and flexibility.

This article provides an in-depth analysis of a low-temperature torsion test conducted on aluminum alloy conductors used in wind power cables. The study evaluates:

By analyzing these factors, we assess whether aluminum alloy conductors can effectively replace copper conductors in new energy applications.

Copper conductors are widely used due to their high conductivity and durability. However, aluminum alloys offer several key advantages:

| Factor | Copper Conductors | Aluminum Alloy Conductors |

|---|---|---|

| Cost | Expensive | 40%–60% cheaper |

| Weight | Heavy | 30% lighter |

| Conductivity | 100% IACS (benchmark) | 61%–65% IACS (compensated by larger cross-section) |

| Flexibility | High | Improved with alloy composition |

| Corrosion Resistance | Excellent | Moderate (requires protective coating) |

➡ Conclusion: Aluminum alloy conductors offer a significant cost and weight advantage, making them ideal for large-scale wind farm installations.

To evaluate the torsion resistance of aluminum alloy conductors, two common alloy compositions were selected:

| Alloy Type | Strength (MPa) | Ductility (%) | Conductivity (% IACS) |

|---|---|---|---|

| 6101 | 100–145 | 21–25 | 61.2 |

| 8030 | 100–145 | 21–25 | 61.5 |

➡ Key Design Insight: A hybrid structure combining 6101 and 8030 alloys was tested to optimize torsion resistance and electrical performance.

After 2,000 torsion cycles, the samples were examined for structural integrity. Key observations included:

| Observation | 6101 Alloy | 8030 Alloy |

|---|---|---|

| Outer Layer Condition | No visible damage | No visible damage |

| Core Strand Fractures | 2–3 broken strands | 1–2 broken strands |

| Surface Cracks | Minor | More prominent |

➡ Conclusion: 8030 alloy exhibited slightly better fracture resistance, making it more suitable for low-temperature applications.

Mechanical testing before and after the torsion test showed a moderate reduction in strength and ductility:

| Property | Before Test | After 2,000 Cycles | Change (%) |

|---|---|---|---|

| Tensile Strength (MPa) | 107 | 101 | -5.6% |

| Ductility (% elongation) | 23.1 | 15.1 | -34.6% |

➡ Key Finding: Aluminum alloy conductors maintain mechanical strength but lose ductility over time, which may impact long-term performance.

One of the main concerns when replacing copper with aluminum is the impact on electrical resistance.

| Property | Before Test | After 2,000 Cycles | Change (%) |

|---|---|---|---|

| Conductivity (% IACS) | 61.5 | 61.1 | -0.65% |

➡ Conclusion: Minimal impact on conductivity was observed, confirming that aluminum alloys can reliably conduct electricity even after torsion stress.

| Application | Requirements | Aluminum Alloy Suitability |

|---|---|---|

| Wind Power Cables | High flexibility, torsion resistance | ✅ Suitable |

| Solar Power Wiring | Lightweight, corrosion-resistant | ✅ Suitable |

| Electric Vehicle Charging Cables | High conductivity, durability | ⚠ Needs further testing |

| High-Voltage Power Transmission | Maximum conductivity | ❌ Not recommended |

➡ Final Verdict: Aluminum alloy conductors are well-suited for wind and solar energy applications but may not fully replace copper in high-voltage or extreme mechanical stress environments.

The low-temperature torsion test confirmed that aluminum alloy conductors are a viable alternative to copper in wind power cables, offering:

✔ Cost and weight advantages

✔ Adequate torsion resistance

✔ Minimal impact on electrical performance

✅ Adopt aluminum alloy conductors for wind and solar power cables.

⚠ Further testing is needed for electric vehicle and high-voltage applications.

With ongoing material innovations, aluminum alloys have the potential to replace copper in many next-generation energy applications, contributing to more sustainable and cost-effective power transmission solutions.