Time: 2025-03-29 12:19:53 Source: Henan Province Jianyun Cable Co., Ltd.

Keywords:

Wind power, cable cross-section, economic optimization, power fluctuation, transmission efficiency, renewable energy, grid integration, cost-benefit analysis

In a wind farm, electricity generated by turbines is transmitted to the power grid via cables. These cables are made of conductive materials like copper or aluminum, and their cross-sectional area (CSA) — the thickness of the conductor — determines:

Transmission Capacity: Larger CSA means more current can flow without overheating.

Power Loss: Smaller CSA increases resistive losses.

Cost: Larger CSA leads to higher material and installation costs.

Traditionally, engineers select cable CSA based on rated output and technical constraints. However, this ignores a key aspect of wind farms: power output is never constant.

Wind speed changes frequently, which results in power output fluctuations. Designing cables solely based on maximum capacity leads to oversized cables, unnecessary costs, and underutilization. Conversely, undersizing can result in high power losses and safety risks.

The goal: Find an optimal balance between cable cost and transmission efficiency by considering the real-world fluctuation pattern of wind power output.

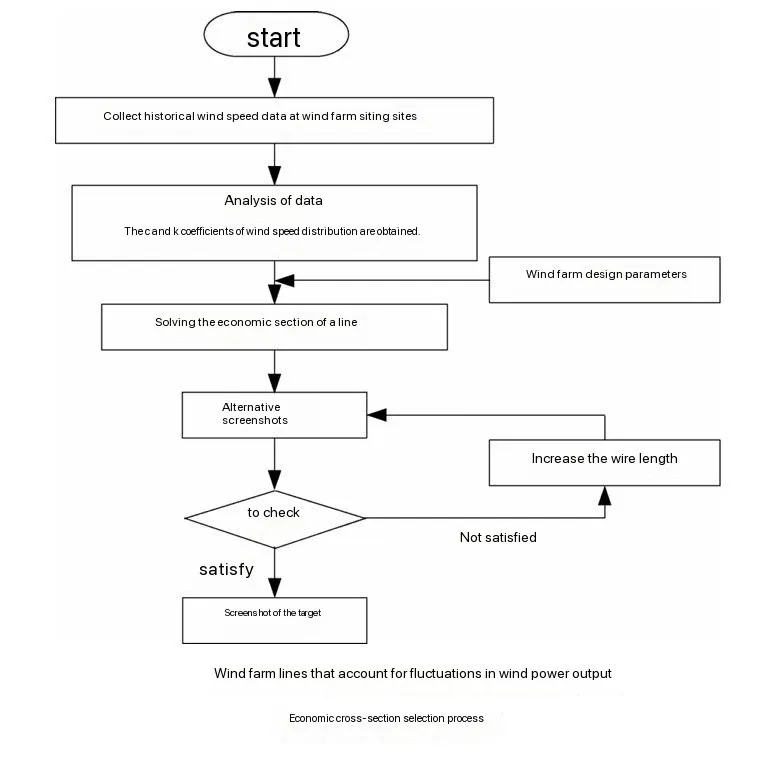

The paper introduces a probabilistic economic optimization model. Here's a simplified breakdown:

The study analyzes historical wind power output data from a real wind farm over one year. It identifies the probability distribution of output levels.

The total cost includes:

Cable Investment Cost: Direct cost based on cable size.

Power Loss Cost: Economic value of energy lost due to resistive heating.

Operation & Maintenance Cost: Ongoing expenses.

Penalty Cost: For potential overload risks.

Using statistical analysis, the authors derive an economic current density (A/mm²) — an indicator used to determine the optimal CSA, factoring in both cost and fluctuation risk.

Different cable CSA options are simulated using actual output data, and their total costs are compared to identify the most economical solution.

The study demonstrates that taking output fluctuation into account results in a smaller and more cost-effective cable CSA selection compared to conventional methods. Specifically:

| Parameter | Traditional Design | Proposed Method |

|---|---|---|

| Design Principle | Rated output | Statistical output fluctuation |

| Cable CSA (Example case) | Larger | Reduced (by up to 15%) |

| Investment Cost | Higher | Lower |

| Power Loss Cost | Lower | Slightly Higher (but offset by lower investment) |

| Total Economic Cost (over lifecycle) | Higher | Lower (by ~8-12%) |

Result:

The study suggests that the lifecycle total cost of wind farm cable systems can be reduced by up to 12% without compromising safety or efficiency, simply by integrating fluctuation analysis.

This research provides valuable insights for the growing renewable energy sector, especially for developers, engineers, and policymakers involved in wind farm planning.

Practical and data-driven:

The model is grounded in real-world wind farm data, enhancing its applicability.

Balances cost and reliability:

By accepting a small increase in power loss, the method achieves greater overall economic benefit.

Scalable approach:

Can be applied to various wind farm sizes and locations.

Dependent on accurate wind data:

If historical wind output data is not reliable, the optimization may be compromised.

May require regulatory adjustments:

Current grid standards may need to adapt to allow fluctuation-based cable sizing.

This model could help reduce infrastructure costs for future wind farms by millions of dollars over their lifetime, improving the overall cost-competitiveness of renewable energy. It aligns with global goals to:

Increase renewable energy share

Optimize energy infrastructure investment

Enhance grid reliability

By adopting this methodology, governments and energy companies can support the transition to clean energy without excessive capital expenditure.

Imagine two wind farms:

| Wind Farm A (Traditional) | Wind Farm B (Optimized) |

|---|---|

| Cables sized for maximum possible output | Cables sized based on statistical fluctuation analysis |

| High upfront cable costs | Moderate cable costs |

| Minimal power loss but large oversizing | Slightly higher power loss but balanced by lower costs |

| Higher total lifecycle cost | Lower total lifecycle cost |

Which one would you choose?

For long-term profitability and efficient resource use, Wind Farm B's approach is smarter — and that's what this paper proves.

The study "Economic Selection of Wind Farm Cable Cross-Section Considering Wind Power Output Fluctuation" delivers a practical, forward-thinking solution for modern energy systems. By factoring in the inherent variability of wind power, engineers can design more economical and sustainable transmission systems.

This methodology is not only a technical improvement but also an economic strategy that supports the global shift towards renewable energy.

Zhang, Z., et al. "计及风电出力波动的风电场导线经济截面选择."

(Economic Selection of Wind Farm Cable Cross-Section Considering Wind Power Output Fluctuation)