Time: 2025-03-11 14:03:30 Source: Henan Province Jianyun Cable Co., Ltd.

The wire and cable industry is a critical sector that supports power transmission, telecommunications, and industrial infrastructure. However, quality and safety issues such as counterfeit products, non-compliant materials, and lack of transparency have posed significant risks in recent years.

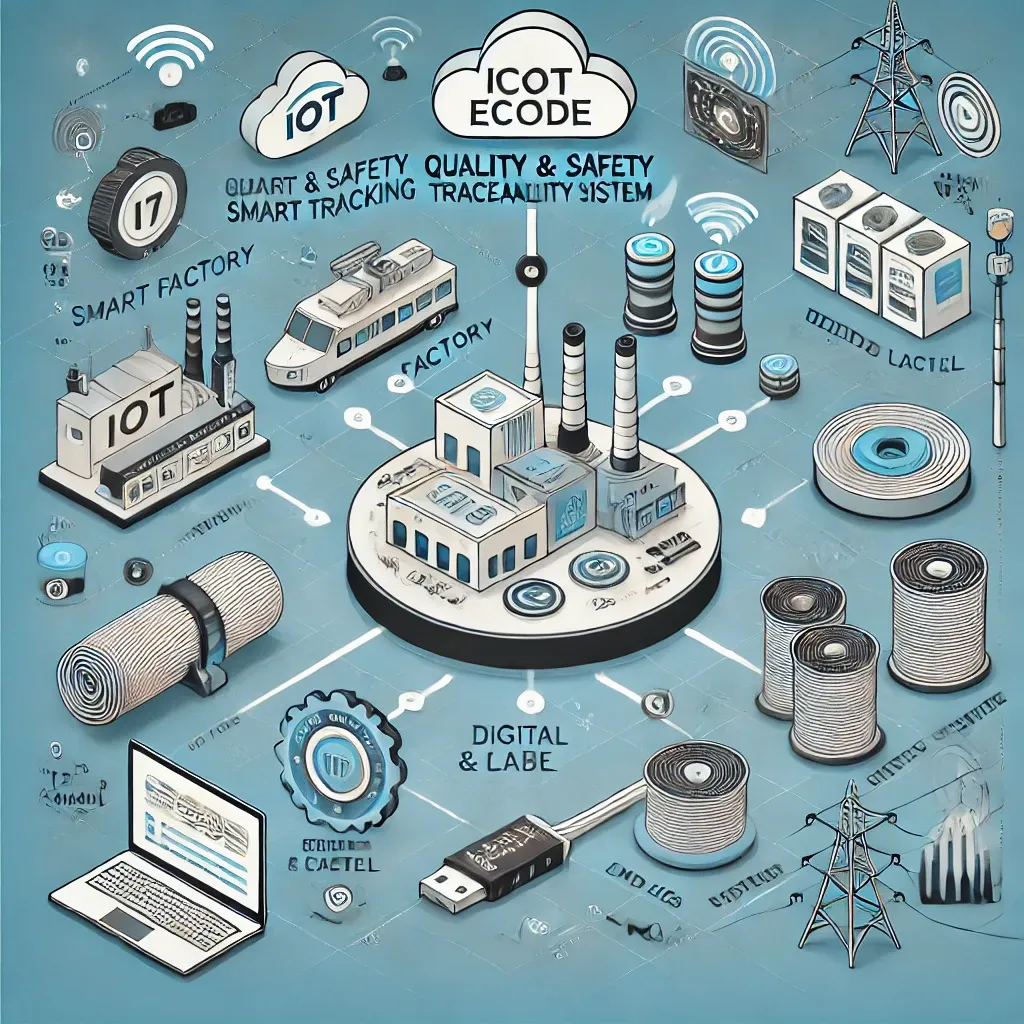

To address these challenges, quality and safety traceability systems have been introduced using Ecode identification and IoT-based tracking technologies. This article explores:

By leveraging big data, digital identification, and intelligent supervision, the industry aims to establish a transparent, efficient, and secure production and supply chain network.

Despite improvements in regulatory frameworks, quality issues persist in the wire and cable industry:

A digitalized traceability system ensures:

✔ End-to-end tracking of wire and cable production.

✔ Real-time monitoring for safety and compliance.

✔ Standardized product labeling, improving verification processes.

The traceability system is built around Ecode identification, an IoT-based system that assigns a unique digital identity to each cable product.

The system operates at three levels:

| Level | Function |

|---|---|

| National-Level Platform | Centralized quality data management, risk monitoring |

| Industry-Level Platform | Standardization of coding and data sharing |

| Enterprise-Level Platform | Implementation of tracking in production, sales, and logistics |

➡ Ecode identification acts as the "digital fingerprint" for each product, enabling seamless data exchange across platforms.

| Function | Description |

|---|---|

| Encoding and Labeling | Assigns Ecode128 unique identifiers to each product. |

| Data Storage and Integration | Links production, sales, and logistics data. |

| Information Query System | Allows real-time verification of product authenticity. |

| Automated Quality Checks | Monitors compliance using AI and big data analytics. |

➡ Implementation Benefits: The system reduces fraud, ensures regulatory compliance, and enhances supply chain efficiency.

A large-scale Chinese cable manufacturer implemented Ecode identification and real-time monitoring to enhance product quality and market transparency.

| Company Name | Sun Cable Ltd. |

|---|---|

| Annual Production | 1.2 million km of cables |

| Main Products | Power cables, communication cables |

| Market | Domestic and export markets |

Step 1: Product Labeling with Ecode

Step 2: Integration with Manufacturing Systems

Step 3: Supply Chain Digitalization

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Quality Defect Rate | 2.5% | 0.6% |

| Counterfeit Cases Detected | 57 per year | 10 per year |

| Supply Chain Traceability | 30% visibility | 90% visibility |

➡ Key Takeaway: Digital traceability improved defect detection, reduced counterfeiting, and enhanced operational transparency.

| Aspect | Recommendation |

|---|---|

| Industry Standardization | Develop globalized Ecode standards for interoperability. |

| AI-Powered Quality Control | Implement machine learning for anomaly detection in production. |

| Blockchain-Based Security | Enhance data integrity and anti-counterfeiting measures. |

| Expansion to Other Sectors | Apply traceability systems to renewable energy cables, aerospace wiring, etc. |

➡ Conclusion: Integrating IoT, AI, and blockchain technologies will further enhance transparency, security, and efficiency in the wire and cable industry.