Time: 2024-12-16 01:25:16 Source: Henan Province Jianyun Cable Co., Ltd.

Electric wire refers to a conductor, typically made of copper or aluminum, used to transmit electricity from one point to another. It plays a critical role in electrical systems, powering devices, machinery, and infrastructure.

Electrical wires are composed of several key components, each serving a specific function to ensure the wire’s ability to conduct electricity safely and efficiently. Below are the main components typically found in electrical wires.

Purpose: The conductor is the core element of an electrical wire that carries the electric current from one point to another.

Materials:

Copper: The most common and preferred material due to its excellent conductivity, flexibility, and durability.

Aluminum: Less conductive than copper but used for cost-effective solutions and in high-voltage applications (e.g., power transmission lines).

Alloys: Sometimes, a combination of metals is used to improve properties like corrosion resistance or tensile strength.

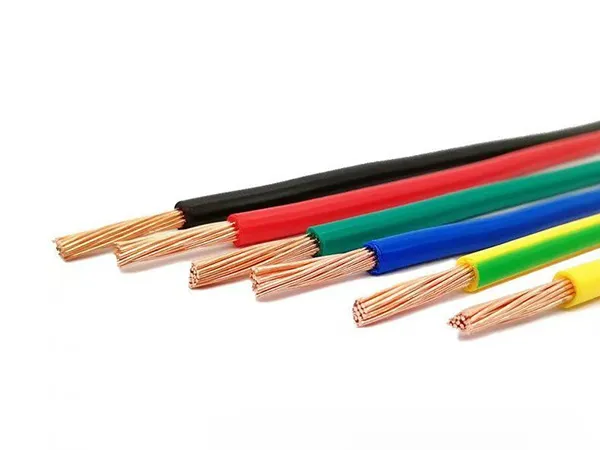

Types:

Solid Conductors: A single piece of metal wire. They are more durable but less flexible than stranded wires.

Stranded Conductors: Multiple thin strands of metal twisted together. They provide greater flexibility and are less prone to breakage when bent or moved frequently.

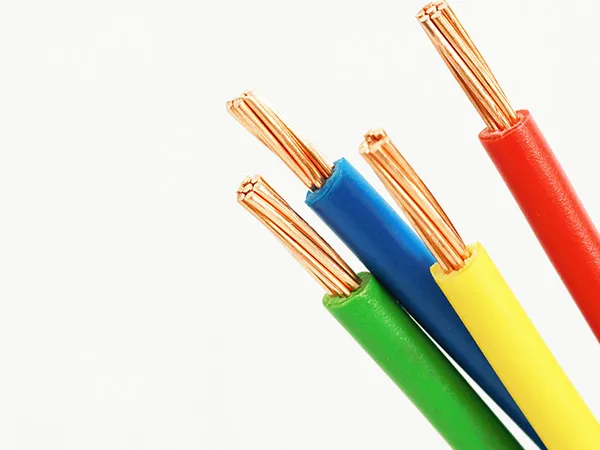

Purpose: Insulation surrounds the conductor to prevent accidental electrical contact, short circuits, or electrical shocks. It also protects the wire from environmental factors like moisture, heat, and chemical exposure.

Materials:

PVC (Polyvinyl Chloride): Commonly used due to its cost-effectiveness, durability, and resistance to moisture, oil, and UV light.

XLPE (Cross-Linked Polyethylene): Offers better thermal and electrical properties than PVC, including higher temperature resistance and better insulation performance.

Teflon: Known for high resistance to heat, chemicals, and flame.

Rubber: Used for flexible wires where mobility and resistance to environmental wear are needed.

EPR (Ethylene Propylene Rubber): Offers better resistance to heat and ozone.

Properties:

Dielectric Strength: The ability of the insulation material to resist electrical breakdown.

Temperature Rating: Insulation materials have a specific temperature range they can withstand before degrading.

Purpose: The outer layer of a wire, which provides mechanical protection and environmental shielding. The jacket prevents abrasion and damage to the insulation and conductor.

Materials: Often made from a durable, flame-retardant material such as:

PVC: Most commonly used for general applications.

Rubber: Flexible and resistant to chemicals and oils.

LSZH (Low Smoke Zero Halogen): Used for applications where fire safety and minimal smoke emission are critical.

Polyethylene: Used in outdoor or underground wires due to its resistance to moisture and UV radiation.

Purpose: Protects the wire from electromagnetic interference (EMI) or radio-frequency interference (RFI), ensuring the integrity of the signal or power being transmitted.

Types of Shielding:

Foil Shielding: A thin layer of metal foil that covers the conductor(s) to provide basic EMI protection.

Braid Shielding: A mesh of fine copper or aluminum wires braided around the conductor for more robust protection against EMI.

Combination Shielding: A mix of foil and braided shielding for the highest level of protection.

Applications: Used in wires for sensitive electronics, control systems, telecommunications, and data transmission.

Purpose: A grounding conductor may be included to provide a path for fault currents, reducing the risk of electrical shock or fire. This is especially important in high-voltage or industrial wiring.

Types:

Bare Wire: A simple uninsulated wire that is grounded to a safe location.

Insulated Grounding Wire: A wire with insulation that is connected to a grounding system.

Applications: Electrical systems requiring safety grounding, like home appliances, industrial machinery, and power distribution systems.

Purpose: Fillers are materials used to maintain the wire's shape, strength, and flexibility, especially in cables with multiple conductors. They help prevent the conductors from shifting inside the insulation.

Materials:

Non-conductive fillers: Such as paper or plastic that support the structure without conducting electricity.

Strength members: Materials like aramid fibers (e.g., Kevlar) or steel wires that provide additional tensile strength and prevent stretching or damage to the wire.

Purpose: In some wires, multiple individual conductors are bundled together to form a pair or a group of conductors that carry different signals or currents.

Types:

Paired Wires: Two conductors twisted together, commonly used for telecommunications and low-voltage applications.

Multicore Wires: Multiple individual conductors inside a single cable, often used for power distribution, control systems, or signal transmission.

Purpose: In some cables, reinforcement is used to improve the mechanical strength and protect the wire from physical damage.

Materials:

Steel Armor: Provides physical protection from impacts and is used in armored cables.

Fiberglass: Sometimes used for additional tensile strength in flexible wires.

Summary of Components in Electrical Wires:

Conductor: Copper, aluminum, or alloy wires that carry the electrical current.

Insulation: Materials like PVC, rubber, and XLPE to prevent accidental electrical contact.

Jacket: The outer layer that protects the wire from environmental and mechanical damage.

Shielding: Foil or braided shielding used to protect from electromagnetic interference.

Grounding: A safety feature to prevent electrical shock and fire risk.

Fillers: Non-conductive materials that maintain the wire's structure.

Strands or Pairs: Multiple conductors grouped together for complex wiring.

Reinforcements: Additional layers to improve the mechanical strength of the wire.

These components work together to ensure the wire is safe, durable, and suitable for its specific application. The exact combination and structure of components depend on the wire's intended use, whether for power transmission, signal communication, or specialized industrial purposes.