600V 14awg PVC/Nylon Insulation SHIELDED TRAY CABLE with U L Listed

4cores XHHW/PVC TYPE TC Control Cable

450/750v Copper Wire Shield Control Cable 1.5mm2 2.5mm2 4.0mm2 for Control Syste

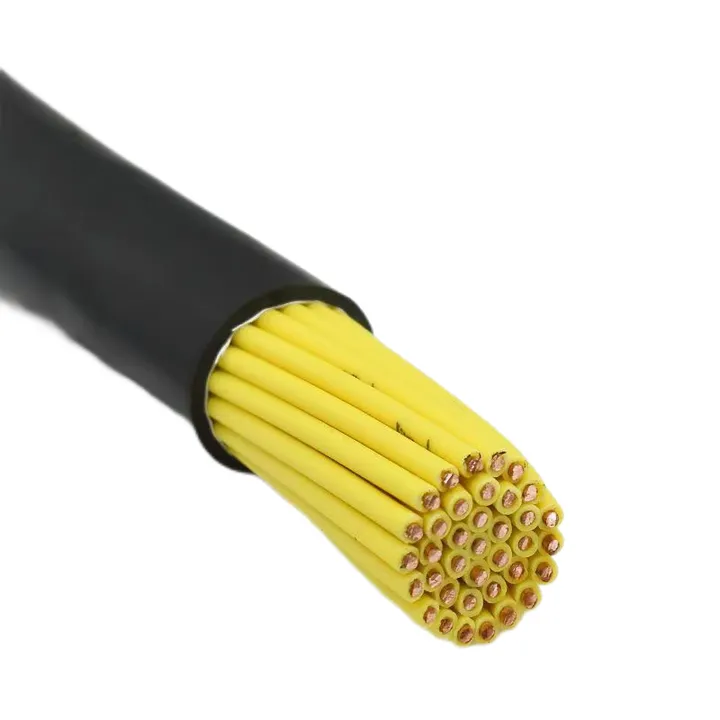

450/750V 37 Core 1.5mm2 2.5mm2 PVC Insulated and Pvc Sheathed KVV Control Cable

XLPE Insulated Armouring Control Cable

JYXL Brand 450/750V Flexible PVC Cable Multi-Core Stranded Copper Conductor 1.5m

JYXL Brand Factory Low Price 450/750V KKV Control Cables with a High Degree of S

JYXL Brand 450/750V KVV Control Cable 1.5mm 2.5mm Copper Stranded Conductor PVC

When selecting or specifying control cables, it is crucial to understand the various technical aspects that determine the cable's performance, compatibility, and safety for a specific application.

We are a manufacturer of a full range of control cables providing you with