XLPE insulated power cables for rated voltages of 1 kV (Um = 1,2 kV) is used to

600/1000V XLPE Insulated Cables (IEC 60502-1) are designed for power distributio

The outer PVC (Polyvinyl Chloride) sheath offers additional protection against m

NYY cable, also known as PVC-insulated power cable, is designed for power transm

This 0.6/1kV aluminum conductor cable is designed with cross-linked polyethylene

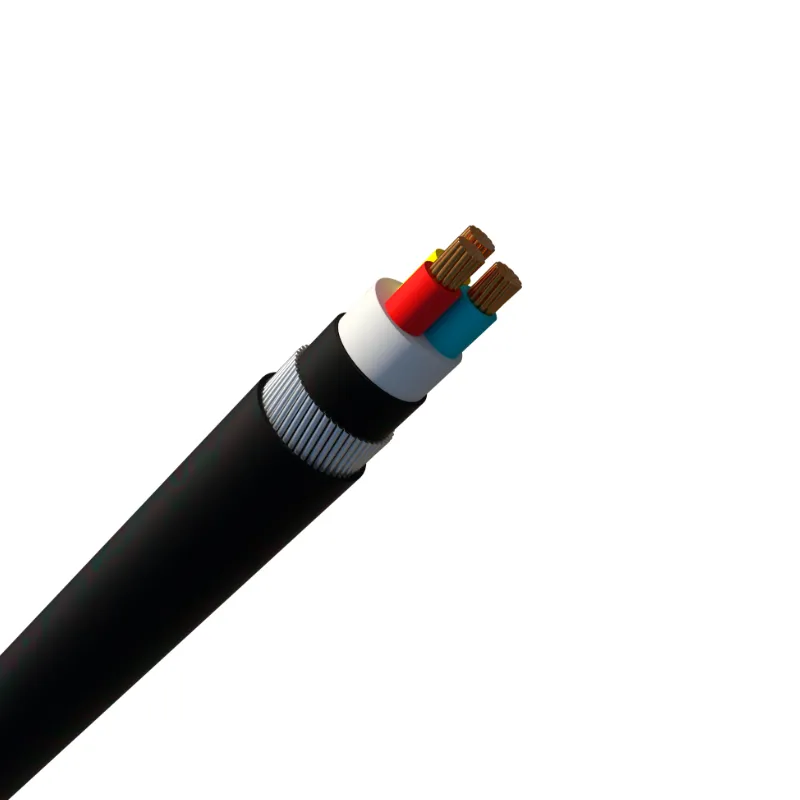

The 0.6/1kV AL/XLPE/STA/PVC cable is a reliable low-voltage power cable designed

The 0.6/1kV AL/XLPE/SWA/PVC Cable is a robust and reliable power cable designed

The WDZBN-YJY power cable features a low smoke halogen-free design, ensuring a s

We are a manufacturer of a full range of Low Voltage Power Cables providing you with

JIANYUN Low Voltage Power Cables are designed with specific features to ensure safe, efficient, and reliable electricity transmission. These features vary depending on the type of cable and its intended application.

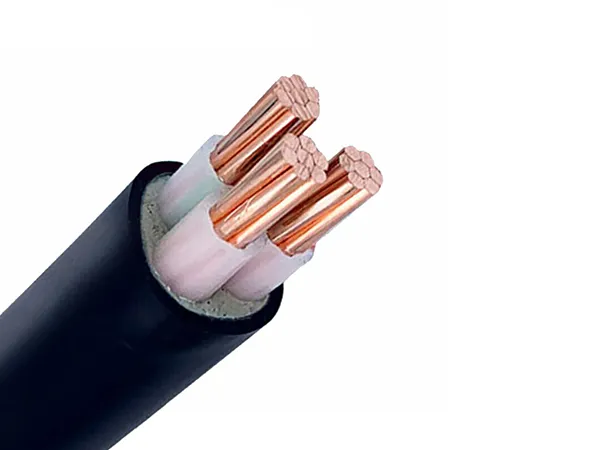

High Conductivity: Usually made of copper or aluminum for excellent electrical conductivity.

Flexibility: Fine-stranded conductors improve flexibility for installations in tight spaces.

Corrosion Resistance: Conductors are often treated or coated to resist corrosion in harsh environments.

Electrical Insulation: Prevents current leakage and protects users from electric shocks.

Materials:

PVC (Polyvinyl Chloride): Common for low voltage, cost-effective, and durable.

XLPE (Cross-Linked Polyethylene): Used in medium and high-voltage cables for high thermal and mechanical resistance.

Rubber: Used for flexible and high-temperature applications.

Outer Sheath: Protects against environmental factors like moisture, chemicals, UV radiation, and abrasion.

Armoring (Optional): Provides additional strength to withstand mechanical stress in underground or industrial applications.

Materials: Steel or aluminum wire/tape.

Heat Resistance: Insulation and sheath materials can handle specified temperature ranges without degrading.

Fire Resistance: Specialized cables maintain functionality during fire or delay flame spread.

Low Voltage: Designed for applications up to 1kV.

Medium Voltage (MV): Handles voltage from 1kV to 35kV.

High Voltage (HV): Used for voltages above 35kV in transmission systems.

Waterproofing: Some cables are designed to resist water penetration, crucial for underground and submarine cables.

UV Resistance: Ensures longevity in outdoor applications.

Oil and Chemical Resistance: Used in industrial environments where exposure is frequent.

Low Capacitance: Reduces energy loss and improves efficiency.

Shielding: Protects against electromagnetic interference (EMI) in sensitive applications.

Flexible Design: Essential for movable or portable equipment.

Stranded Conductors: Enhance flexibility without compromising conductivity.

Low Smoke Zero Halogen (LSZH): Reduces toxic fumes during fire, ideal for confined spaces.

It can carry a large amount of traffic in a short period of time.

Color Coding: For easy identification of conductors (e.g., live, neutral, earth).

Durable Materials: Designed to withstand mechanical, electrical, and environmental stresses over decades.

Weatherproofing: Ensures performance in extreme weather conditions.