Home / Product / Medium Voltage Power Cable / Medium Voltage CU/XLPE Power Cable

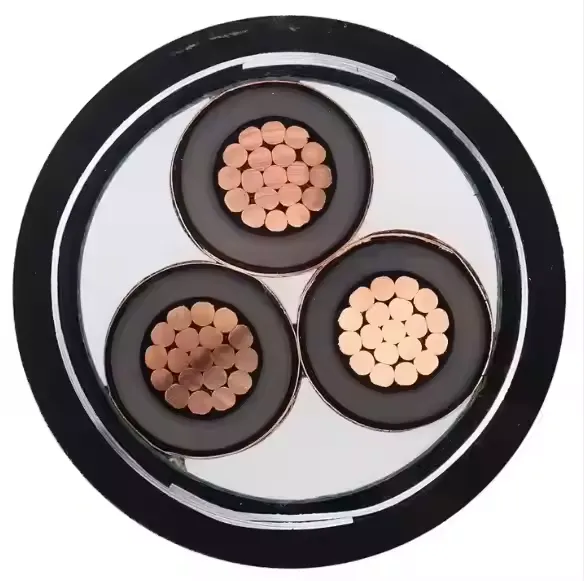

JianYun Medium Voltage Cross-linked Cable is the perfect power transmission solution for your construction engineering needs. Engineered with a copper conductor and XLPE (cross-linked polyethylene) insulation, this cable guarantees exceptional conductivity, superior heat resistance, and robust durability, making it ideal for demanding construction environments. The YJV- CU/XLPE/PVC model is designed for medium voltage applications at 1.8/3kV and 3.6/6kV, featuring a 3-core configuration and a protective PVC outer sheath. Proudly manufactured in Henan, China under the trusted JianYun brand, this cable is crafted with high-quality XLPE/PVC + copper materials and is ISO9001/CCC certified, ensuring a safe and dependable power supply for all your construction endeavors.

| Key attributes | |

|---|---|

Industry-specific attributes |

|

| Insulation Material | xlpe |

| Conductor Material | Copper |

| Application | Construction |

| Jacket | PVC |

Other attributes |

|

| Type | Medium Voltage |

| Model Number | YJV- CU/XLPE/PVC |

| Size | 3x185mm |

| Voltage | 1.8/3Kv 3.6/6Kv |

| Core | 3 |

| Conductor | Copper |

| Insulation | XLPE |

| Sheath | PVC Shealth |

| Material | XLPE/PVC + copper |

| Color | Black |

| Place of Origin | Henan, China |

| Brand Name | JianYun |

| Certificate | ISO9001/CCC |

| Application | construction |

|

Three Core 1.8/3KV (Um=3.6KV)

|

|||||

|

Nom. Cross- Section Area

|

Nom. Insulation Thickness

|

Nom. Sheath Thickness

|

Approx. Overall Diameter

|

Approx. Weight

|

|

|

CU

|

AL

|

||||

|

mm2

|

mm

|

mm

|

mm

|

kg/km

|

|

|

10

|

2

|

1.8

|

23

|

650

|

460

|

|

16

|

2

|

1.8

|

24

|

840

|

540

|

|

25

|

2

|

1.8

|

26

|

1160

|

680

|

|

35

|

2

|

1.8

|

29

|

1490

|

820

|

|

50

|

2

|

1.9

|

32

|

1900

|

1000

|

|

70

|

2

|

2

|

36

|

2580

|

1290

|

|

95

|

2

|

2.2

|

40

|

3440

|

1640

|

|

120

|

2

|

2.3

|

43

|

4220

|

1950

|

|

150

|

2

|

2.4

|

46

|

5090

|

2290

|

|

185

|

2

|

2.5

|

50

|

6240

|

2730

|

|

240

|

2

|

2.7

|

56

|

8030

|

3430

|

|

300

|

2

|

2.8

|

60

|

9890

|

4100

|

|

400

|

2

|

3.1

|

68

|

12530

|

5150

|

|

500

|

2.2

|

3.3

|

75.7

|

16680

|

7510

|

|

630

|

2.4

|

3.5

|

84.9

|

21770

|

10040

|

|

Three Core 3.6/6KV (Um=7.2KV)

|

|||||||

|

Nom. Cross- Section Area

|

Nom. Insulation Thickness

|

Copper Tape Screen Area (0.1mm)

|

Copper Wire Screen Area

|

Nom. Sheath Thickness

|

Approx. Overall Diameter

|

Approx.Weight

|

|

|

CU

|

AL

|

||||||

|

mm2

|

mm

|

mm2

|

mm2

|

mm

|

mm

|

kg/km

|

|

|

10

|

2.5

|

4.2

|

16

|

2

|

30

|

980

|

790

|

|

16

|

2.5

|

4.6

|

16

|

2

|

31

|

1190

|

890

|

|

25

|

2.5

|

5

|

16

|

2.1

|

34

|

1560

|

1080

|

|

35

|

2.5

|

5.4

|

16

|

2.2

|

37

|

1930

|

1270

|

|

50

|

2.5

|

5.9

|

16

|

2.3

|

40

|

2370

|

1480

|

|

70

|

2.5

|

6.6

|

16

|

2.4

|

43

|

3110

|

1820

|

|

95

|

2.5

|

7.3

|

16

|

2.5

|

47

|

4000

|

2200

|

|

120

|

2.5

|

8

|

16

|

2.6

|

50

|

4820

|

2550

|

|

150

|

2.5

|

8.5

|

25

|

2.8

|

54

|

5770

|

2970

|

|

185

|

2.5

|

9.4

|

25

|

2.9

|

58

|

6960

|

3460

|

|

240

|

2.6

|

10.4

|

25

|

3.1

|

65

|

8940

|

4340

|

|

300

|

2.8

|

11.4

|

25

|

3.3

|

70

|

10980

|

5190

|

|

400

|

3

|

12.6

|

35

|

3.5

|

79

|

13820

|

6440

|

|

500

|

3.2

|

13.9

|

35

|

3.7

|

87

|

19100

|

10755

|

|

630

|

3.2

|

15.3

|

35

|

4

|

95

|

30470

|

13150

|

NYY cable, also known as PVC-insulated power cable, is designed for power transm

50mm2 70mm2 95mm2 120mm2 ACSR Moose Bear Dog Rabbit Squirrel Weasel Raccoon

High-Quality Insulation: This CU/XLPE/STA/PVC 1.8/3Kv 3.6/6Kv Medium Voltage Arm

The three core cables are designed for distribution of electrical power with nom